什么是塑料薄膜造粒机?

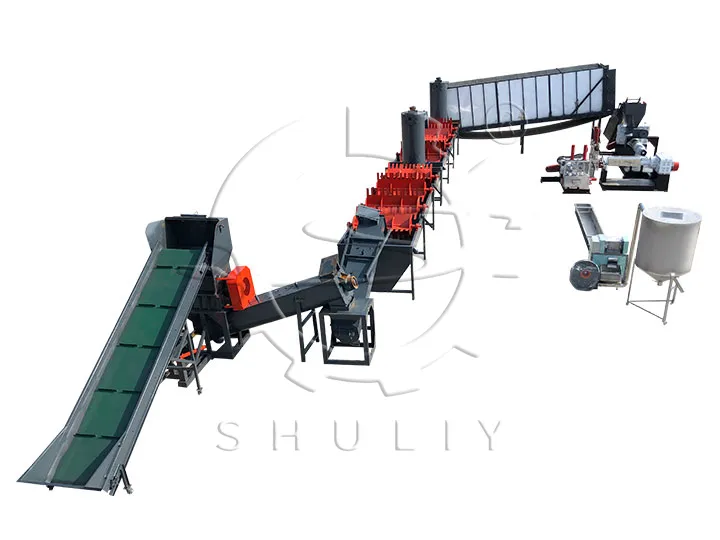

PP PE塑料造粒机是一种将废旧塑料制品或塑料边角料加工成颗粒状物料以制造新塑料制品的回收机械。

可加工各种薄膜类塑料,产量200kg/h-1000kg/h。 如果您正在寻找塑料回收颗粒机,欢迎在网站上留言您的需求。

舒力塑料造粒机如何帮助您的业务?

Shuliy 是值得信赖的塑料造粒机制造商。我们可以为您提供:

- 根据您的需求提供产品配置方案供您选择

- 邀请您参观机器生产现场或工厂,讲解整个工作流程

- 协助您安装PP PE塑料造粒机并提供操作说明

- 提供易损件,帮助您及时更新机器配件

塑料造粒机规格

| 原料 | PP PE LDPE等,如大棚膜、农用地膜、塑料薄膜、拉伸膜、保鲜膜、编织袋、包装膜等。 |

| 最终产品 | 用于繁殖的均匀高质量塑料颗粒 |

| 输出范围 | 180公斤/小时-420公斤/小时 |

| 造粒型 | 水环造粒或拉条造粒 |

| 加热装置 | 熨斗加热、电磁加热或陶瓷加热 |

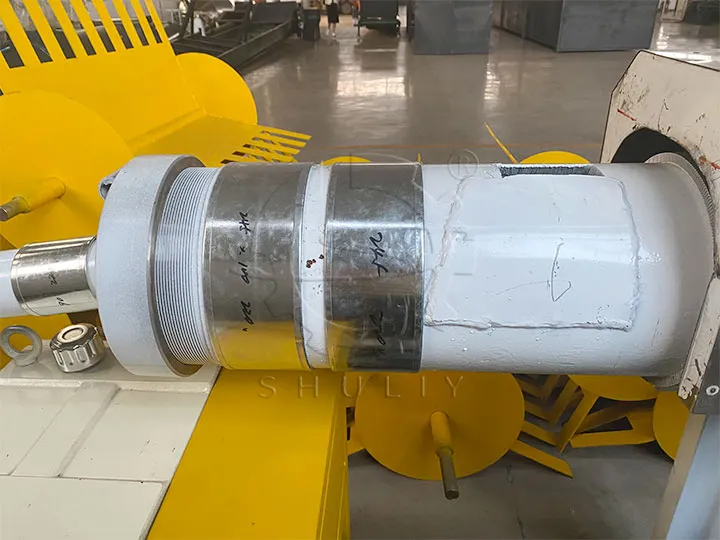

| 模头 | 电动齿轮模头、自动滤渣器或液压模头 |

| 保修单 | 一年保修,无需额外费用 |

| 技术援助 | 安装指导、现场安装、操作指导 |

PP PE塑料薄膜造粒机有多种型号,尺寸、产量等不同,根据螺杆直径来命名。具体参数如下:

| 模型 | SL-125 | SL-135 | SL-150 | SL-180 | SL-210 | SL-220 |

| 螺杆直径(m) | 125 | 135 | 150 | 180 | 210 | 220 |

| 电机功率(KW) | 30 | 37 | 37 | 55 | 75 | 90 |

| 尺寸(米) | 2.6*0.7*0.7 | 2.8*0.7*0.7 | 3.0*0.7*0.8 | 3.2*0.7*0.8 | 3.5*1*1 | 3.8*1.2*1 |

| 产量(公斤/小时) | 180 | 200 | 300 | 350 | 380 | 420 |

塑料回收颗粒机是如何工作的?

PP PE塑料造粒机的基本设计

PP PE塑料造粒机由进料口、电机、减速机、加热装置、螺杆、模头、压制室、出料口组成。

- 读: 塑料挤出机三种加热系统的比较

- 读: 3 塑料造粒机主要结构

工作原理

PP PE塑料造粒机的基本原理是将塑料废料熔化并挤出成型。然后经切割、冷却得到成品塑料颗粒。步骤如下:

- 原料从塑料造粒机的进料口投入,由进料装置送入机内。 自动送料器.

- 在塑料薄膜造粒机的加热下,塑料熔化并形成均匀的熔体。

- 当熔体的流动性达到要求时,从机器的螺杆中流出。

- 流出的熔体进入塑料薄膜造粒机的挤出区,通过模头挤出成条状。

塑料颗粒机销售成功案例

作为优秀的塑料薄膜造粒机制造商,我们已将塑料薄膜造粒机销往加纳、尼日利亚、埃塞俄比亚、阿曼、南非、印度等多个国家。

客户对我们的机器赞不绝口。借助PP PE塑料造粒机,客户赚取利润的同时也为当地的环境保护做出了贡献。

请点击 博客案例 获取相关案例信息。

塑料颗粒有市场吗?

塑料颗粒是塑料制品的基础材料,广泛应用于电子、汽车、家电、医疗、建筑等行业。

目前,全球塑料颗粒市场规模已超过US$1.5万亿。随着环保意识的不断增强,越来越多的国家和地区限制或禁止使用一次性塑料制品。这将导致对塑料颗粒的需求增加。

因此,塑料颗粒销售市场未来仍有较大的增长潜力。

最新塑料造粒机出售

我们一直致力于节能型PP PE塑料造粒机的研发。不久前我厂开发了一批全新的塑料回收颗粒机。它们更加节能高效,生产的塑料颗粒质量也更好。

我们的塑料颗粒机价格合理。如果您想来参观我们的塑料薄膜造粒机工厂,请在网站上留言。我们的工作人员会安排相关事宜。