纸浆蛋托生产线高效地将废纸转化为可生物降解、环保的蛋托。这一绿色、可持续的过程可用于蛋类包装、水果托、咖啡杯托、工业缓冲包装等多种用途。

蛋托生产线的原材料和最终产品

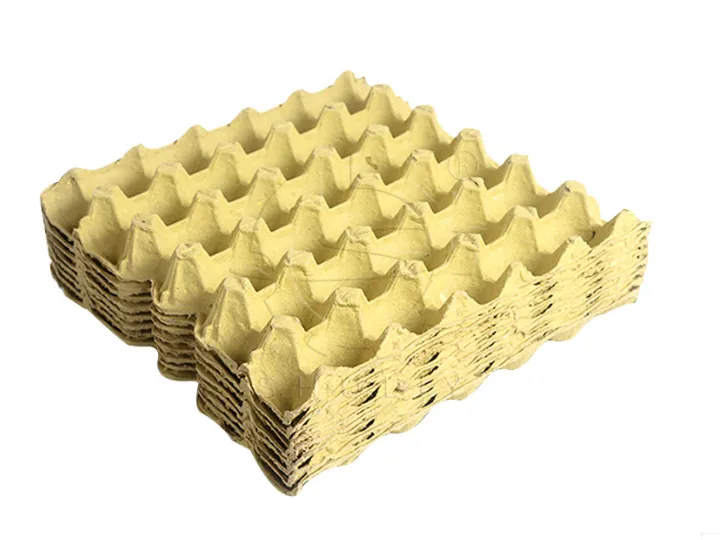

蛋托主要由纸浆制成,纸浆的来源广泛,包括旧报纸、纸板和其他类型的废纸。纸质蛋托生产线适应性强,生产成本低,原材料易于获取,并且具有良好的环保效益,这与当前绿色包装的发展趋势相符。

该设备可以通过制浆、成型、干燥和包装等工艺高效地生产各种纸浆模制产品。客户可以通过更换模具和调整生产工艺,根据具体的生产要求控制纸托的形状、颜色和厚度,实现多样化定制。

纸浆模制产品包括蛋托、苹果托、咖啡杯托、鞋托和电子产品内托。这些产品广泛应用于食品包装、工业保护、物流、运输以及许多其他领域。

通过 Shuliy 蛋托制造厂最大化收益

Shuliy蛋托生产线的产能为每小时1000到7000个,能够高效地将废纸转化为高价值的包装产品。单个蛋托的生产成本仅约为0.026美元至0.04美元,而在国际市场上的售价可以达到0.07美元至0.10美元,甚至更高。单个蛋托的利润率可以高达150%-250%!

- 该设备使用广泛的廉价、易获取的原材料,并以低成本提供快速的结果。每吨废纸的成本约为210美元,可以生产约12,500个蛋托。

- 设备操作简单,节省人力。每个蛋托的平均人工成本约为 0.003 美元.

- 低能耗:蛋托制造机节能。每个蛋托的平均电费约为 0.003 美元.

- 有多种干燥选项。根据当地气候和燃料市场选择最佳干燥选项.

- 您可以通过选择托盘的形状、大小和颜色来自定义成品。每千克燃料可以染色3000-4000个蛋托;因此,添加颜色的成本低于每个托盘0.0006美元。

蛋托制造的详细工作流程

完整的蛋托生产线由四个模块组成:制浆、蛋托成型、干燥和热压包装.

制浆:浆料机、浆料泵、搅拌器

- 打浆机以 1:10 的比例将废纸和水混合以制成浆料。然后将浆料放入混合罐中.

- 颜料、防水胶和其他添加剂被引入罐中以改性浆料.

- 调制后的浆料被泵入浆料供应罐,在那里加入水以将浆料稠度稀释至3%-5%,以满足成型要求。

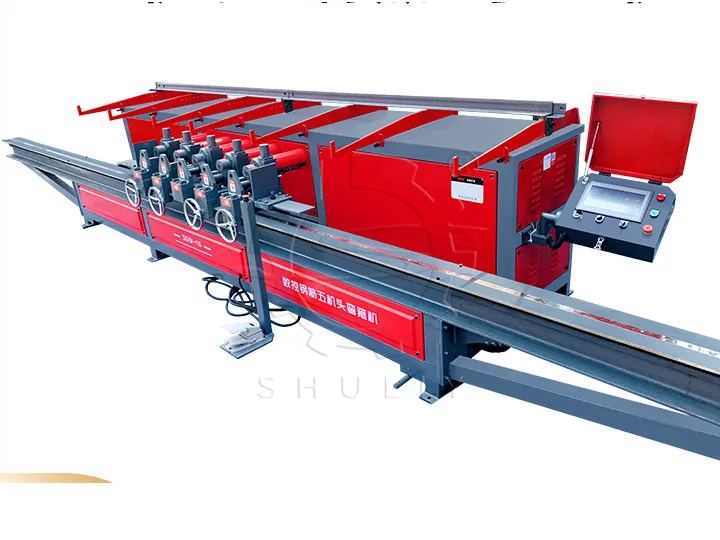

蛋托成型:蛋托成型机,真空泵,空气压缩机

- 在真空泵的帮助下,蛋托成型机的模具紧密贴合于纸浆上,形成湿蛋托。

- 纸浆中的多余水分通过不锈钢过滤器排出,并进入水池以便重复使用。

- 空气压缩机将成型的湿蛋托吹送到移动带上,进入下一个干燥阶段。

湿蛋托的干燥:

脱模后,蛋托需要干燥以增强其结构稳定性和整体强度。 Shuliy 蛋托生产线支持多种干燥方法,包括手动干燥、民用隧道干燥和多层金属干燥系统。这些方法可以满足不同客户的生产能力要求和现场条件。

我们可以根据您现场的大小、预算和当地气候条件设计最合适的干燥方案和生产线布局,以帮助您实现高效、节能的生产。

热压与包装:热压机,推堆机,打包机

- 热压机通过高温和高压将蛋托压缩得更紧密、更平坦,提高了抗压强度和美观性。

- 堆叠机会根据设定的数量(例如,100堆)自动将蛋托分组成堆,以提高效率并便于计数。

- 打包机将堆叠的蛋托打包并固定,使其更易于运输。

联系我们获取定制的蛋托生产线!

Shuliy提供一整套设备,从废纸到蛋托捆,并提供一站式服务,包括现场规划、运输方案设计、技术指导、上门安装、一年免费保修等。如果您感兴趣,请随时与我们联系!