Shuliy Machinery offers two specialized waste tire cutter models designed to process both standard truck tires and large OTR (off-the-road) tires. With hydraulic power, durable alloy blades, and efficient cutting performance, our machines are essential for modern tire recycling lines aiming to reduce labor and improve throughput.

Why Use a Waste Tire Cutter?

In a complete tire recycling process, the waste tire cutter plays a vital role in pre-cutting large tires into smaller blocks. This pre-processing step significantly eases the load on shredders and crushers, improves working efficiency, and extends the life of downstream equipment. Whether you’re recycling standard tires or heavy-duty engineering tires, choosing the right cutter ensures safe and effective material handling.

Raw Materials & Final Output

Input tires:

- Truck tires with or without steel wire

- OTR mining tires with bead removed

Output size:

- ≤900 mm rubber chunks or clean slices

- Uniform size for easy feeding into shredders or grinders

These compacted blocks are much easier to shred, store, or transport.

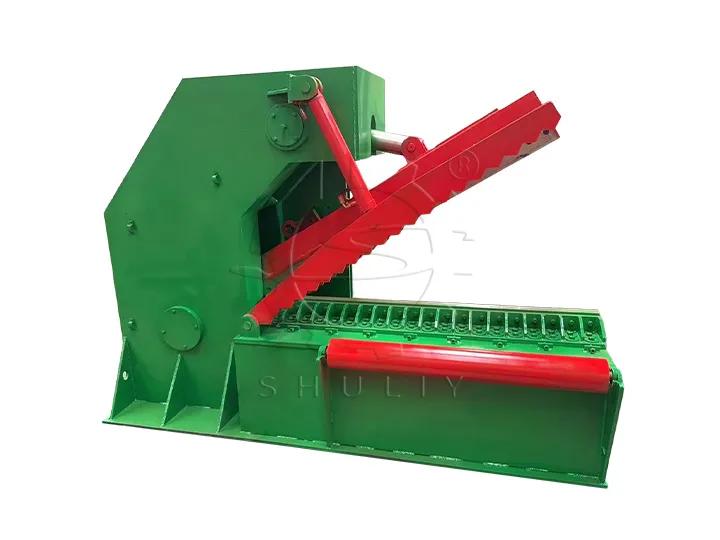

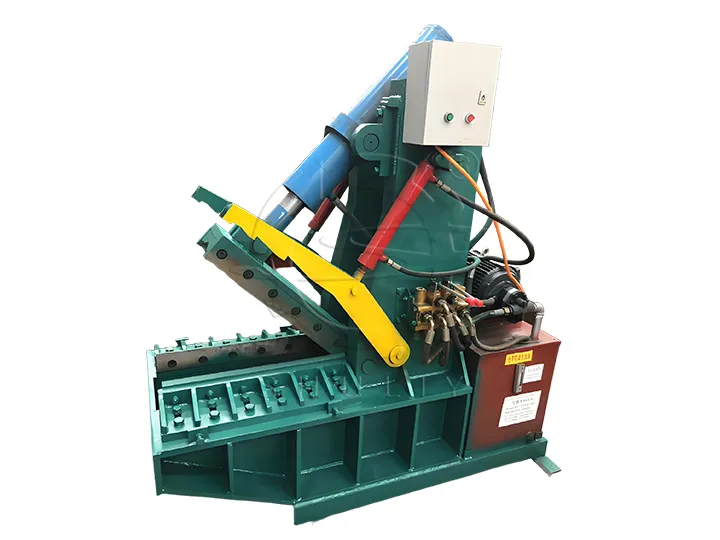

Two Models to Cover All Tire Sizes

| Model | Standard Tire Cutter | OTR Tire Cutter |

|---|---|---|

| Power | 7.5 kW | 7.5 kW |

| Tire Size Range | 900–1200 mm truck tires | 1400–4000 mm OTR tires (beadless) |

| Capacity | 60 tires/hour | 2 cuts/minute |

| Weight | 1400 kg | 7200 kg |

| Dimensions | 1.7 × 0.8 × 1.85 m | 3.13 × 1.65 × 2.7 m |

| Blade Material | Cr12MoV Alloy Steel | Cr12MoV Alloy Steel |

| Packaging | Wooden crate (1.9 × 1 × 2.1 m) | Unpacked |

The standard waste tire cutting machine is ideal for pre-processing truck tires by cutting them into ≤900 mm rubber blocks, while the OTR tire cutter is specifically designed for slicing large industrial tires after bead wire removal.

Complete standard tire recycling line and OTR tire recycling plant

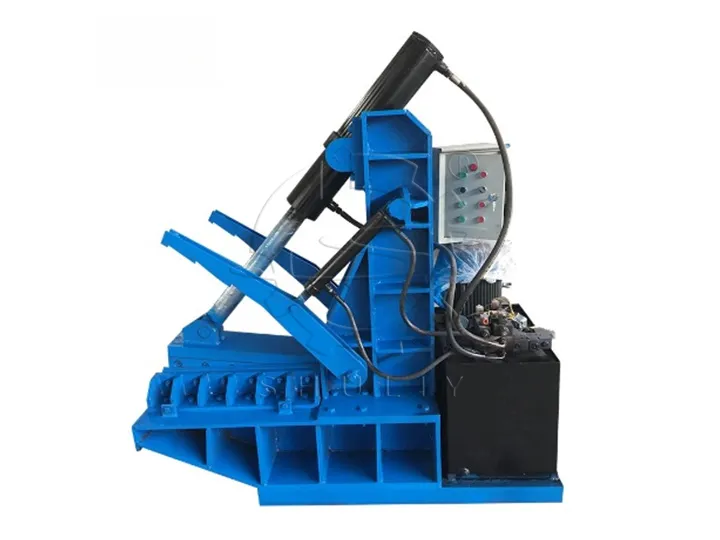

Working Principle of the Waste Tire Cutter

Shuliy’s waste tire cutters are hydraulically driven. The operator positions the tire in the cutting chamber, and with one press, the hydraulic system activates the high-strength blades to slice through the rubber. The process is fast, safe, and clean — no sparks, no flying dust, and minimal labor input.

Customer Case: Indonesia Mining Industry

In 2024, an Indonesian rubber recycling company purchased both models from Shuliy to handle local truck tires and imported OTR mining tires. After one month of operation, the customer reported:

“The waste tire cutter from Shuliy cut our labor time in half and increased our shredding efficiency by over 40%. It’s a must-have for any tire recycling plant.”

Get a Custom Solution for Your Recycling Needs

Whether you’re dealing with commercial truck tires or massive engineering tires, Shuliy’s waste tire cutters offer a reliable, cost-effective solution. Contact us today for:

- Model recommendations based on your tire size

- Full tire recycling line configurations

- Free quotation and video demonstration

👉 Let us help you transform waste into value with powerful tire cutting technology.