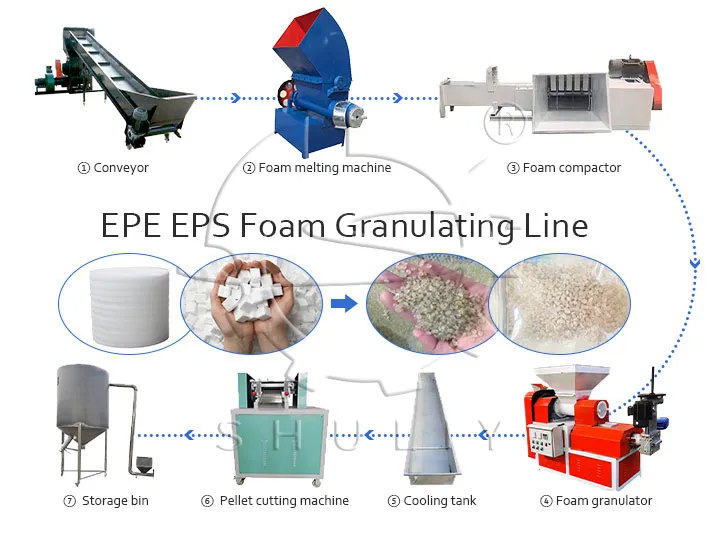

The entire foam packaging material recycling line consists of a cold pressing machine, a hot melting machine, a plastic pellet-making machine, etc. The following are operation and maintenance tips on how to properly use them.

Operational Precautions

Precautions to Take Before Using a Machine

- Be sure to connect the power lines correctly to prevent electrical shock.

- Check that the foam packaging material recycling machines are properly aligned and not leaning or suspended, as this can cause malfunctions or even safety incidents.

- Check the hydraulic system, transmission system, etc. to ensure they are functioning properly. If there are any jams or loose parts, have a professional repair them immediately.

- Make sure the machine is not overloaded.

Cautions for Use

Staff should wear protective gear to avoid material splashing and don’t put their hands in the foam packaging recycling machine. The specific operation tips are as follows.

Cold pressing machine

- Pay attention to the temperature setting, although it is a cold press machine, the mechanical friction will generate heat. If overheating occurs, you can apply lubricant to keep it running smoothly or check the electrical components to see if a wiring fault is causing overheating. In addition, place the machine in a well-ventilated area.

- The foam packaging material fed is of a suitable size to prevent the machine from getting stuck.

Holt melting machine

- Like the cold compressing machine, be sure the temperature set is suitable. The melting point of foam packaging products made from different materials is different, and different temperatures should be set. If the temperature is too high or too low, it will affect the effect.

- Check the exhaust system to avoid the production of harmful gases during the melting process.

pellet making machine

- Set the granulator speed properly to avoid producing uneven particles due to either too fast or too slow speed.

- Pay attention to the color and shape of the output material, and make adjustments to the machine promptly.

Post-use Daily Maintenance

- Clean the foam packaging material recycling machine interior promptly, especially the hot melt machine, to prevent the heating efficiency from being lowered due to the accumulation of residues.

- Record the cause of the failure and repair it promptly.

- Regularly check the lubrication of the transmission system and bearing parts of the machine, and replace the mold of the granulator in time.

Conclusion

These guidelines may seem complicated, but they are quite easy to follow. Proper maintenance and regular servicing of the machine can extend its lifespan and improve its efficiency. If you have any needs or questions about the foam packaging material recycling machine, please click the link at the bottom right to contact us.