The plastic shredding process is a crucial first step in plastic recycling. It greatly impacts the efficiency and quality of the entire recycling operation, supplying high-quality raw materials that are easier to process for subsequent washing and pelletizing.

However, plastic recyclers are always faced with the challenges of high energy consumption, rapid wear and tear of equipment, and poor applicability of raw materials during shredding. So how can we optimize the plastic shredding process to achieve cost reduction and efficiency?

Selecting the right plastic crusher

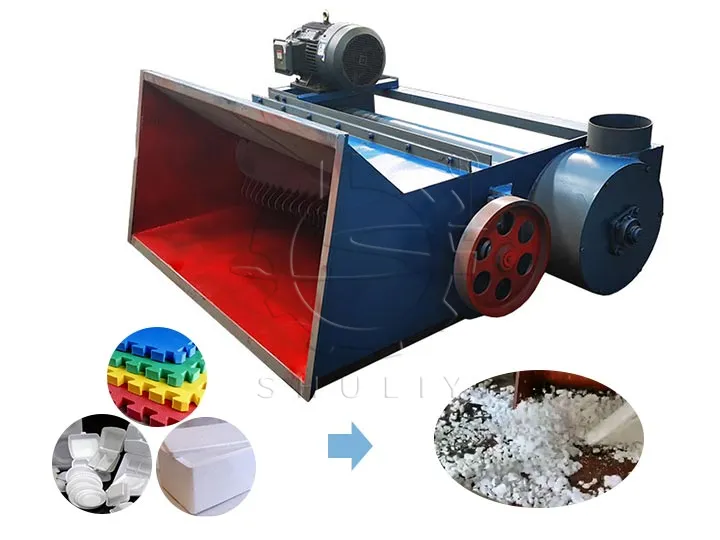

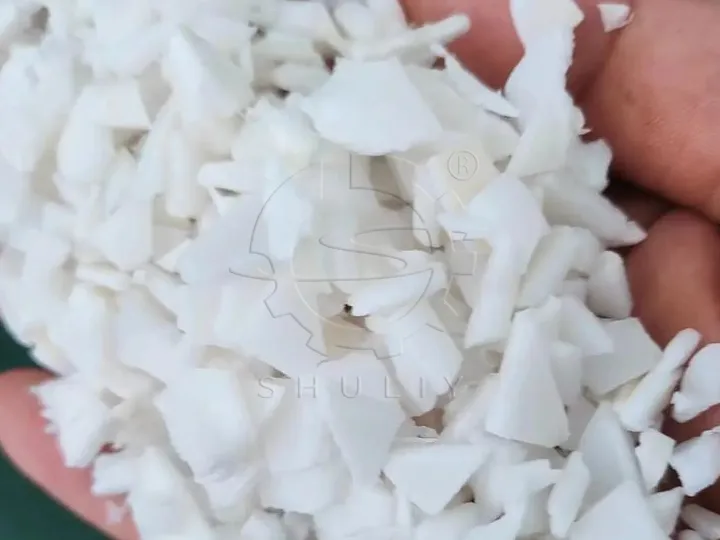

The plastic shredder is designed for efficient and uniform crushing. It quickly processes many waste plastic materials, such as HDPE drums, extrusion scraps, plastic films, etc., through the synergistic shearing action of fixed and moving knives. According to the types and characteristics of recycled plastics, Shuliy’s plastic crushers are divided into the following types:

- PET shanga ya chupa: Kwa kutumia mfumo wa blade sahihi, inaweza kushughulikia kwa ufanisi maumbo mengi ya chupa za plastiki, kama vile chupa za mviringo na chupa za gorofa, na kuepuka chembe ndogo mno wakati wa mchakato wa kusaga.

- Kusaga Plastiki Imara: Kwa blade zenye nguvu kubwa, inaweza kushughulikia kwa ufanisi na kwa ufanisi plastiki ngumu anuwai, ikiwa ni pamoja na PP, PE, PVC, HDPE, ABS, n.k.

- Kusaga filamu ya plastiki: Kwa blade kali, inaweza kushughulikia filamu nyepesi na laini za plastiki, kama vile: filamu ya ufungaji wa plastiki, filamu ya kilimo, n.k., ambayo inaweza kuepuka kwa ufanisi tatizo la kusongwa na kuziba.

- Foam Crusher: Inafaa kwa EPS, EPP, EPE, na povu nyepesi nyingine, huondoa hewa kwenye povu kwa ufanisi, na kupunguza ujazo.

Depending on the raw material and production requirements, select the most appropriate plastic shredding machine to improve plastic availability and subsequent recycling efficiency. Please send us your production profile for a recommended custom crushing solution.

Optimize the parts configuration of plastic crusher

A plastic crusher consists of blades, motor, screen, feed inlet and so on. Optimization of key components in terms of material, structure, performance and other aspects can also improve the efficiency of plastic crushing.

Blades: Shuliy plastic crusher is made of high-quality stainless steel or 60Si2Mn material, which is wear-resistant, heat-resistant, and corrosion-resistant, increasing the strength and durability of the equipment. In addition, for different types of raw material characteristics, the use of different blade designs such as slant cut, and straight cut, optimizes the crushing effect.

Motor: For large hard plastics, the use of high-power motors can ensure the continuity and stability of the plastic shredding process. For soft plastics, the use of low-power motors can save energy. Shuliy motor adopts frequency conversion control and energy-saving design, which can reduce energy consumption and flexibly adjust the speed according to the actual demand.

Screen Mesh: Use different aperture meshes to adjust the size of the discharged debris to suit different recycling requirements. The use of wear-resistant materials can reduce screen mesh loss and improve service life.

Adjustment parameters in Plastic Shredding Process

Adjusting plastic crushing parameters can effectively improve the crushing effect, such as:

- Rotational speed: choose the right rotational speed to ensure the best effect of plastic shredding, to avoid excessive crushing or insufficient crushing.

- Feed rate: too much feed will cause clogging, and too little feed will aggravate knife wear, energy waste, and uneven and discontinuous crushing.

Safe operation and regular maintenance

Regularly checking the running condition of the equipment and replacing worn parts in time can improve the crushing efficiency. In addition, to optimize the plastic shredding process not only to improve efficiency but also to pay attention to safety protection. The Shuliy plastic crusher is equipped with an overload protection system and emergency stop device, effectively avoiding accidents.

slutsats

By choosing the right plastic crusher, using high-quality plastic parts, optimizing equipment parameters, and so on, you can effectively improve the efficiency of plastic crushing. If you want to get the best plastic shredding solution, please feel free to contact us!