Styrofoam compactor machines and polystyrene melting machines are two types of machines that compress the foam. Many people in the foam recycling business hesitate to choose between these two machines. If you don’t know which machine is more suitable, this blog will solve your confusion.

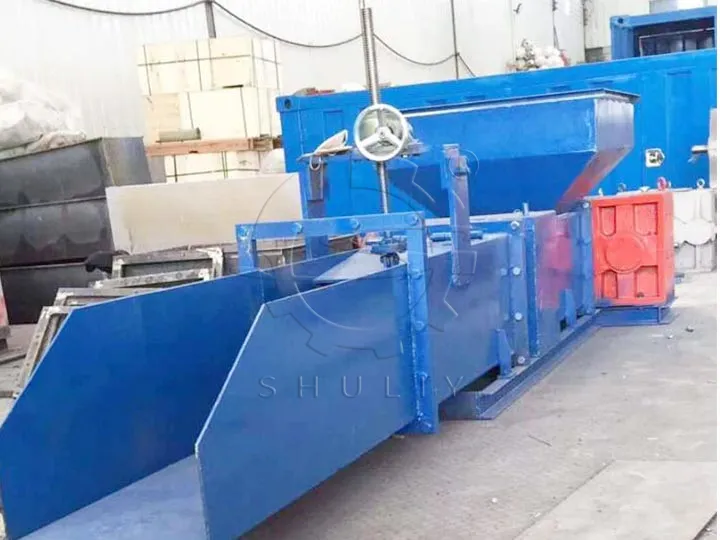

Styrofoam compactor machine

Simple styrofoam compactor compresses foam by generating pressure through screw operation. It can reduce the volume of foam to increase the density, which is convenient for transportation and landfill disposal. Simple styrofoam compactor machine has no odor in the compression process, no need to add chemicals, and no secondary pollution.

EPS hot melting recycling machine

The EPS hot melting recycling machine uses crushing blades to shred the foam into smaller volume blocks. It is filtered through a strainer and shredded again. It is then heated to a molten state by a high-speed rotating screw. Finally, it is cut into blocks by a hydraulic cutter for easy storage and transportation.

simple styrofoam compactor or polystyrene melting machine?

Styrofoam compactor machines do not require heat treatment during the compression process and therefore do not emit odors. In contrast, polystyrene melting machines produce odors during the heat fusion process, and the odors remain even after the fume exhaust design.

EPS hot melting recycling machines have a higher compression ratio of 90:1, while styrofoam compactor machines have a compression ratio of only 50:1. However, simple styrofoam compactors can also meet the needs of most customers.

Moreover, the foam cold press is more environmentally friendly, so it is easier to get permission from the government to use it.

You can choose the right equipment according to the actual production needs.