This plastic film recycling line is designed for soft plastic recycling and pelletizing. We can provide plastic pelletizing lines with different capacities from 200kg/h to 1000kg/h.

Our standard LDPE film washing lines can meet the needs of most plastic film recycling plants. However, we can also design customized solutions with additional machines according to your needs.

What films can be recycled?

Soft plastics made of PP PE LDPE HDPE can be recycled and pelletized with this plastic film recycling line. It can excellently make plastic pellets from agricultural film, stretch film, packaging film, woven bags, PP raffia bags, cast film, trellis film, and so on.

Plastic film recycling line finished display

Our PP woven bags pelletizing machines produce strong and uniformly sized final pellets. Recycled film granules can be used for blown film, tube making, and other plastic injection.

What is the process of plastic pelletizing line?

The recycling process of the recycling line includes crushing, cleaning, drying, granulating, cooling and cutting. The granulation part is done by the plastic film granulator, which is the most important step in the recycling process. For an introduction to plastic film granulators, you can check out this blog: PP PE Plastic Pelletizing Machine For Film Recycling

Main equipment for plastic film recycling plant

Here is an introduction to the configuration of the 200kg/h plastic film recycling plant.

Plastic film crusher

- Application: Crushing plastic film into small pieces.

- Model: SL-600

- Power: 22kw

- Capacity: 600-800kg/h

- Knives: 10pcs

- Knives Material: 60Si2Mn

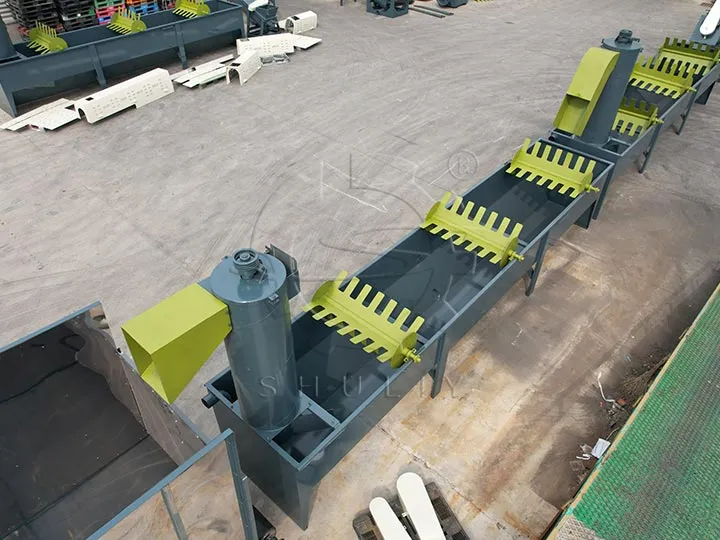

Film washing machine

- Application: Cleaning PP PE film and removing impurities.

- Length:5m

- Width: 1.3m

- Height: 1.2m

- With 2 pcs grapples

Film dryer machine

- Application: Convey materials from washing tank and dewater

- Power: 7.5kw

- Diameter:530mm

Plastic granulator machine

- Application: Melt and extrude the plastic film

- Host pelletizer

- Model: SL-150

- Power: 37kw

- 2.3m screw

Second pelletizer

- Model: SL-125

- Power: 11kw

- 1.3m screw

Cooling tank

- Application: Cooled and cured extruded plastic strips

- Length: 3m

- Material: stainless steel

Pellet cutting machine

- Application: Cutting cooled plastic strips into pellets

- Power: 3kw

- Hob knives

PP woven bags pelletizing machine advantage

- Customized design according to plant space and raw material

- Minimum investment, maximum value

- Good production capacity ensures the purity and quality of the final pellets.

- Stable performance with 24/7 machine operation

Free LDPE film washing line design

We offer three types of plastic film recycling line layouts: “I”, “U” and “L”. Our professional engineers will design the most efficient solution according to your plant layout. Simply leave a message on our website with the relevant information and we will help you free of charge.

“I” type plastic film recycling line

“L” type PP woven bags pelletizing machine

How to choose right agricultural film recycling machine?

There are a few factors to consider when choosing a plastic film recycling line:

- Raw material type: Different types of plastic films require different pelletizing processes and configurations.

- Capacity requirements: Determine the amount of plastic that needs to be processed per day.

- Equipment quality: Select equipment that is of reliable and durable quality to ensure long-term stable production operation.

- Cost and budget: Consider plastic film recycling line purchase and operating costs to ensure compliance with the budget.