A complete set of PET recycling lines consists of several PET recycling machines, including a de-labeling machine, PET crusher machine, plastic float sink tank, hot washing tank, friction washing machine, and PET dryer machine. Waste PET bottles are de-labeled, crushed, washed, dried, and other processes to finally get clean PET flakes.

- Capacity: 500kg/h~6t/h

- Raw Materials: PET plastics

- Final Products: Clean PET flakes

- Customer: PET recyclers, PET plastic container manufacturers, etc.

shuliy PET bottle recycling line Advantages

- Durable, resistant to corrosion, and can be provided CE and ISO certification.

- Simple operation and maintenance with automatic systems.

- Customized machines satisfy each customer’s production needs, including materials, colors, sizes, etc.

- Ranging capacities are suitable for all scales of plastic factories.

- Provide plant layout, operation guide, and on-site installation.

Plastic bottle recycling machine parameters

| Name | Specification | QTY |

| PET crusher machine | Voltage:380V, 50HZ, 3 phase Power: 37+1.5KW+1.5kw Cutter: 9Crsi Output:1000kg/h Screen size: 18mm Thickness of knife plate: 40mm | 1 |

| PET label remover machine | High-speed friction washer | 1 |

| PET flakes washing machine | Voltage: 380V, 50HZ, 3 phase Power: 3KW Outer wall thickness: 4mm Blade thickness: 6mm Equipment size: 5000*1000*1000mm Polyolefin content≤200-300(mg/kg) | 1 |

| PET hot washing machine | Voltage:380V,50HZ,3 phase Power: 7.5KW Barrel length: 3000mm Diameter: 400mm Outer wall thickness: 4mm Blade thickness: 6mm | 1 |

| PET hot wahing machine | Voltage:380V,50HZ,3 phase Motor: 4KW Electromagnetic heating power: 80KW Height: 2000mm Diameter: 1300mm Outer wall thickness: 4mm Bottom thickness: 8mm | 1 |

PET recycling machine raw materials & final products

Our PET flakes hot washing lines are available to recycle all kinds of PET plastics, including the following:

- PET bottles: Mineral water bottles, beverage bottles, cola bottles, etc. Both round and flat bottles can be recycled with this PET recycling machine.

- Packaging made of PET: Food packaging film, PET tray

- PET fiber and other waste PET plastics.

The end product of the PET recycling line is plastic PET flakes, which have high values. Chemical fiber mills use these recycled bottle chips to make polyester fibers. The common towels, T-shirts, and down jackets are made by PET bottle recycling.

How to effectively achieve PET bottle recycling?

PET bottle washing recycling line video

We have successfully delivered a complete PET recycling machine to Nigeria. This is the customer’s factory production video. This video shows the full process of the PET bottles to bottle flakes.

PET flakes hot washing line process

Plastic bottle recycling processes include de-labeling, crushing, sinking, and separating, high-temperature hot washing, friction washing, and drying by the above machines. The specific steps are as follows:

1. De-labeling: Remove the PVC logo paper from the plastic bottle to ensure the purity of the final products.

2. Crushing: Crush plastic bottles into flakes, which is more convenient to deep wash. Made of high-quality steel stainless, the plastic crusher blades are sharp and durable, and the machine has a capacity of 500kg/h~1500kg/h, greatly improving the production efficiency.

3. Sinking and separation: Separate PET bottle flakes from PP bottle caps by density. Lighter materials float on the water surface and flow out through the upper hole, while heavier materials such as stones and metals sink to the bottom and are discharged through the discharge port.

4. Friction washing: Remove any residual caustic soda from the bottle flakes by friction force, whose capacity ranges from 400kg/h to 600kg/h.

5. Hot washing: Add industrial alkali for hot washing in high-temperature water. Remove the grease on the surface of PET bottle flakes and make them cleaner and more transparent.

6. Drying: Drying the rinsed plastic flakes to remove the water from them. If you have a larger production volume, you can also use a drying tube and a wind separator.

How to start your PET recycling business?

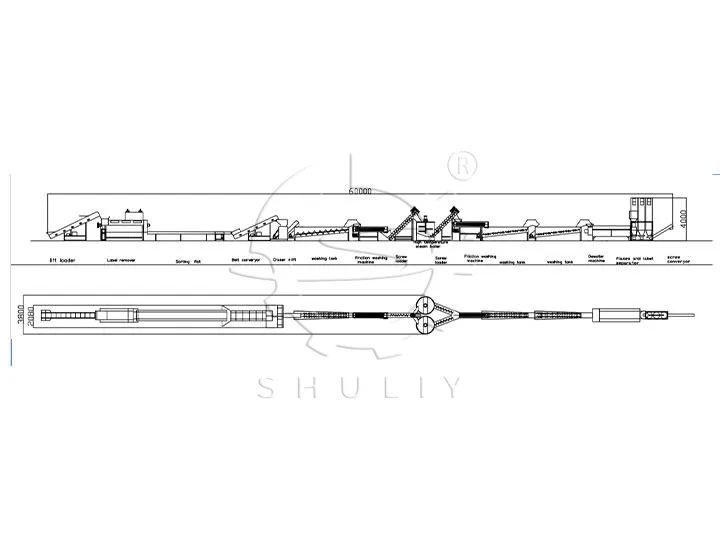

Here is the 1000kg/h PET recycling line design and we can also provide designs for other scales. If you’re interested, please feel free to contact us. We’ll try our best to help you.

- Workers: 6-8

- Plant: Placed in one line. The PET flakes hot washing line covers an area of 60m2.8m4m in length, width, and height.

- Total electrical power: 140kw motor + 190kw heating = 330kw

Recycling plastic bottles machine price

The PET recycling machine price is related to the configuration of the machine you choose.

Some customers choose manual de-labeling. There is no de-labeling machine in his PET bottle washing recycling line, and the price will be lower.

Some customers have dirty raw materials and they need two or more washing machines. The price of such a PET flakes hot washing line configuration will be a little higher.

Please leave a message on the website to tell us your needs. We will customize the PET recycling washing machine for you.