In the plastic recycling industry, plastic bottles that are not strictly cleaned and directly processed by drying are prone to yellowing and odor due to residual pollutants (e.g. grease, glue, organic residues), seriously affecting the recycled PET’ quality and market value. For this reason, we have launched an integrated cleaning system with a friction washer, a sink float tank, and a hot PET flakes washing machine as the core, which thoroughly removes impurities through a scientific step-by-step process and helps enterprises realize high-quality plastic recycling with high efficiency and environmental protection.

Traditional Washing Issues and Our innovative solutions

Traditional pet flakes washing methods rely on manual or simple mechanical processing, making it difficult to completely remove stubborn contaminants (such as label adhesive, ink, sediment, etc.) from the surface of bottle flakes, leading to thermal decomposition of residues in subsequent processing, triggering yellowing and odor. Our system realizes the breakthrough through the following three-step process:

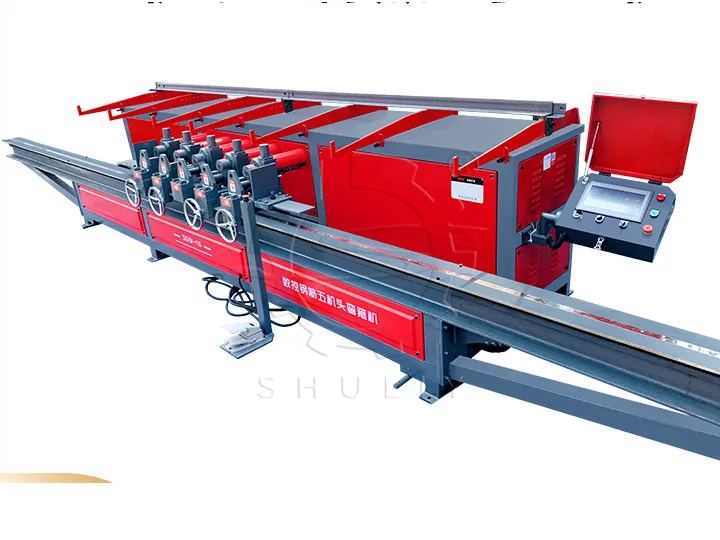

Friction Washer: Deep Stripping of Stubborn Contaminants

- Utilizing a high-speed rotor design, it efficiently removes adhesives, chemical coatings, and surface contaminants through intense friction between bottle pieces and centrifugal force separation.

- Equipped with adjustable water flow rate to suit different contamination levels to ensure thorough cleaning without damaging the material.

Sink Flaot Tank: Precise separation of impurities and pET flakes

- Utilizing the difference in density, light impurities (such as paper, oil and grease) are separated by flotation through water circulation, and heavy particles (such as sediment, metal debris) are precipitated and discharged, significantly improving the purity of raw materials.

- Combined with screen filtration and a circulating water system, it reduces water consumption and subsequent processing load.

Hot washing tank: High-Temperature decomposition of organic residues

- By heating the washing water (special chemicals can be added), deep organic pollutants (such as oil, and grease) are dissolved and removed, and the preset residence time ensures that the pollutants are completely decomposed to avoid yellowing.

- After hot washing with centrifugal dewatering, the humidity of plastic bottle flakes is reduced to less than 1%, reducing drying energy consumption.

The core advantages of our pET flakes washing machine

- High capacity: The friction washer supports continuous feeding, with a capacity of 400-600kg/h, to meet the demand for large-scale plastic bottle recycling.

- Energy saving: Equipped with a water recycling system and wastewater treatment system, which can conserve water resources avoid environmental pollution, and meet the environmental protection standard.

- Low maintenance and long life: The equipment adopts wear-resistant steel and modular design (e.g. removable screen mesh), which is convenient for maintenance.

Successful case of our PET flakes washing process

One of our Nigerian customers has adopted this PET bottle cleaning system and successfully reduced the impurity rate of plastic bottle flakes to less than 2%, the moisture to less than 0.5%, and the bottle flakes are pure and odorless. Its process flow is as follows:

De-labeling → Crushing → Friction washing → Sedimentation and separation → Hot washing → Drying

The high quality of the recycled plastic bottle flakes and the high efficiency of the washing has successfully helped our Nigerian customers to increase their overall competitiveness in the recycled plastic market!

Why choose our plastic bottle washing line?

- Leading technology: integrating the three core technologies of friction cleaning, density sorting, and high-temperature decomposition to efficiently improve the purity of PET bottle flakes.

- Customized service: recommend or customize the plastic bottle cleaning line according to the customer’s production needs and adapt to different capacity requirements.

- High return on investment: reduce raw material waste, energy consumption and labor costs.

conclusion

Enquire now and start a new chapter of high-quality plastic recycling! Through the scientific cleaning process, we help enterprises turn “unqualified waste” into “golden resources”, and promote the sustainable development of the circular economy.