पुनर्नवीनीकृत पीईटी फ्लेक्स पीईटी प्लास्टिक के छोटे टुकड़े होते हैं जिन्हें टुकड़े-टुकड़े करने, धोने और सुखाने सहित कई चरणों के माध्यम से प्लास्टिक की बोतलों, कंटेनरों आदि से बनाया जाता है।

पुनर्नवीनीकरण पीईटी फ्लेक्स का उपयोग इतना व्यापक है कि इसमें कपड़ा, और पैकेजिंग उद्योग आदि शामिल हैं। वे महत्वपूर्ण मूल्य रखते हैं क्योंकि वे न केवल लागत कम करते हैं और उत्पादन दक्षता में सुधार करते हैं बल्कि परिपत्र आर्थिक विकास की उन्नति में भी योगदान देते हैं।

पुनर्चक्रित पीईटी फ्लेक्स का उपयोग क्या है?

रेशे बनाना

पुनर्नवीनीकृत पीईटी फ्लेक्स को पिघलाया जा सकता है और पॉलिएस्टर फाइबर में बदला जा सकता है, जिसमें स्थायित्व, इन्सुलेशन और पहनने के प्रतिरोध जैसी विशेषताएं होती हैं।

पॉलिएस्टर फाइबर कई कपड़ा उत्पादों की मुख्य सामग्री हैं, जैसे कपड़े, पर्दे, कालीन, इत्यादि।

पैकेजिंग कंटेनर बनाना

उपभोक्ता-पोस्ट पीईटी बोतलों को रीसाइक्लिंग प्रक्रियाओं के माध्यम से नई प्लास्टिक पैकेजिंग सामग्री में बनाया जा सकता है। इन्हें आमतौर पर प्लास्टिक पेय की बोतलों, सॉस कंटेनरों, लंच बॉक्स आदि में ढाला जाता है।

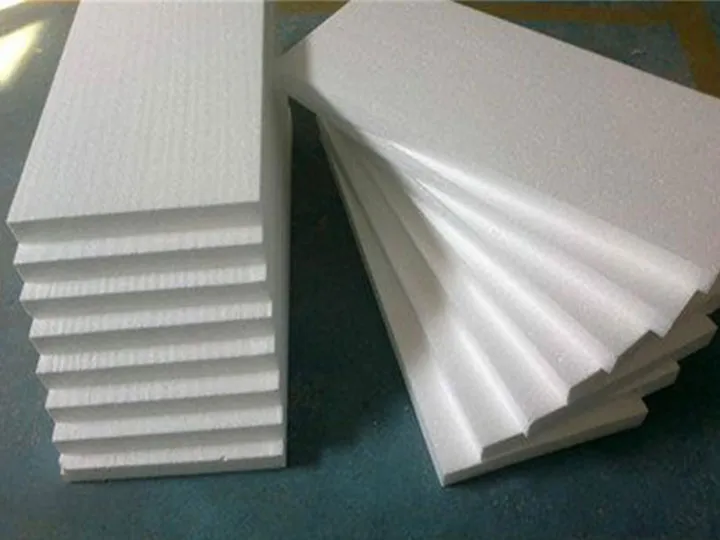

फर्नीचर उत्पादन करना

स्थायित्व की विशेषताओं के कारण, पीईटी प्लास्टिक को पुनर्चक्रित किया जा सकता है और विभिन्न रूपों में ढाला जा सकता है, जो फर्नीचर उत्पादन के लिए अच्छी सामग्री हैं, जैसे कुर्सियाँ, खिलौने, टेबल इत्यादि।

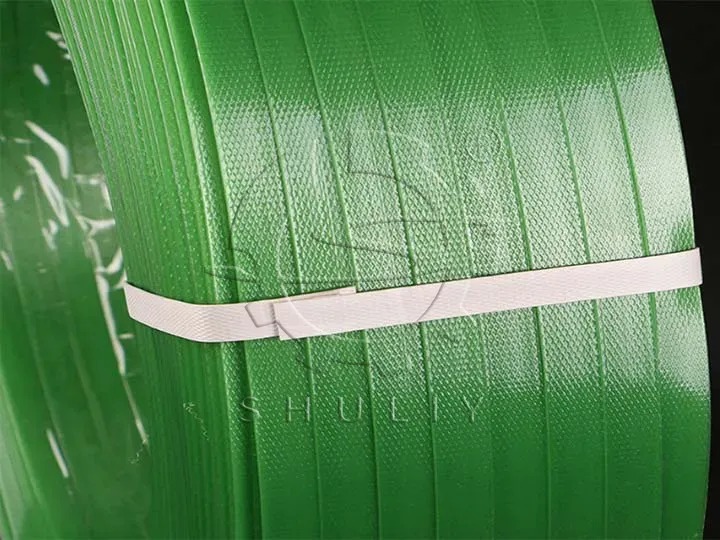

स्ट्रैपिंग सामग्री का उत्पादन

इसे मुख्य कच्चे माल के रूप में पीईटी के साथ एक्सट्रूज़न और यूनिडायरेक्शनल स्ट्रेचिंग द्वारा बनाया जाता है, जिसका उपयोग पॉलिएस्टर पैकेजिंग पट्टियों का उत्पादन करने के लिए किया जा सकता है। यह एक नई प्रकार की पर्यावरण अनुकूल पैकेजिंग सामग्री है जो स्टील वायर और हेवी-ड्यूटी पीपी की जगह ले सकती है।

पीईटी को प्रभावी ढंग से गुच्छों में कैसे पुनर्चक्रित करें?

पुनर्चक्रण प्रक्रियाओं को 5 चरणों में वर्गीकृत किया गया है: छंटाई, लेबल हटाना, कुचलना, धोना और सुखाना।

- छँटाई: अधिकतम दक्षता के लिए खाली गोल बोतलों और चपटी बोतलों को अलग किया जाना चाहिए।

- लेबल हटाना:

- शुद्धता सुनिश्चित करने के लिए डी-लेबल रिमूवर बोतलों से लेबल हटा देता है।

- क्षमता: 800~300 किग्रा/घंटा

- मुंहतोड़:

- शुली प्लास्टिक क्रशर बोतलों को 300~5000 किग्रा/घंटा की गति से छोटे टुकड़ों में काटता है।

- ब्लेड सामग्री: 60Si2Mn

- धुलाई:

- घर्षण वॉशिंग मशीन, सिंक फ्लोट सेपरेशन टैंक और हॉट वॉशिंग टैंक गहराई से धोने और अशुद्धियों को दूर करने में सहयोग करते हैं।

- क्षमता: 400~600 किग्रा/घंटा

- सुखाने: भंडारण के लिए क्षैतिज सुखाने वाली मशीन डीवाटर्स पुनर्नवीनीकृत पीईटी फ्लेक्स। यदि आपके पास बड़ी उत्पादन मात्रा है, तो आप सुखाने वाले उपकरण के रूप में एक सुखाने वाली ट्यूब और एक पवन विभाजक जोड़ सकते हैं।

पीईटी रीसाइक्लिंग मशीन खरीदने के लिए कौन उपयुक्त है?

यदि आप पीईटी रीसाइक्लिंग, प्लास्टिक बोतल उत्पादन, कपड़ा उत्पादन, या अन्य पीईटी-संबंधित क्षेत्रों में शामिल हैं, तो उच्च दक्षता, गुणवत्ता और चौकस सेवा के लिए शुली की पीईटी रीसाइक्लिंग मशीन खरीदने पर विचार करें।

हमारी पीईटी रीसाइक्लिंग मशीनों को आपकी उत्पादन आवश्यकताओं के आधार पर अनुकूलित किया जा सकता है और विभिन्न प्लास्टिक को न केवल पीईटी बोतलों बल्कि बीयर की बोतलों आदि को भी रीसाइक्लिंग किया जा सकता है। यदि आपके पास पुनर्नवीनीकरण पीईटी फ्लेक्स के उपयोग और बनाने के तरीकों के बारे में कोई प्रश्न हैं, तो कृपया बेझिझक हमसे संपर्क करें।