L'usine de recyclage de pneus usagés semi-automatique Shuliy combine des équipements automatisés et un prétraitement assisté par l'homme pour convertir efficacement les pneus usagés (≤1200 mm) en poudre de caoutchouc avec une taille de particule ajustable de 10 à 40 mesh pour une réutilisation. Elle est populaire dans le monde entier en raison de son rapport coût-performance élevé et de sa durabilité.

Caractéristiques clés de l'usine de recyclage de pneus usagés semi-automatique Shuliy

- Large application: Convient à tous les pneus usagés d'un diamètre allant jusqu'à 1200 mm, y compris les pneus de voitures particulières, de camions et d'autobus.

- Rentable: Un choix idéal pour les usines de recyclage de petite à moyenne taille avec des budgets limités.

- Sortie personnalisable: La capacité de production peut être adaptée à vos besoins spécifiques de traitement.

- Taille de poudre de caoutchouc ajustable: La taille finale de la poudre de caoutchouc varie de 0,63 à 2,5 mm avec une pureté de plus de 99 %.

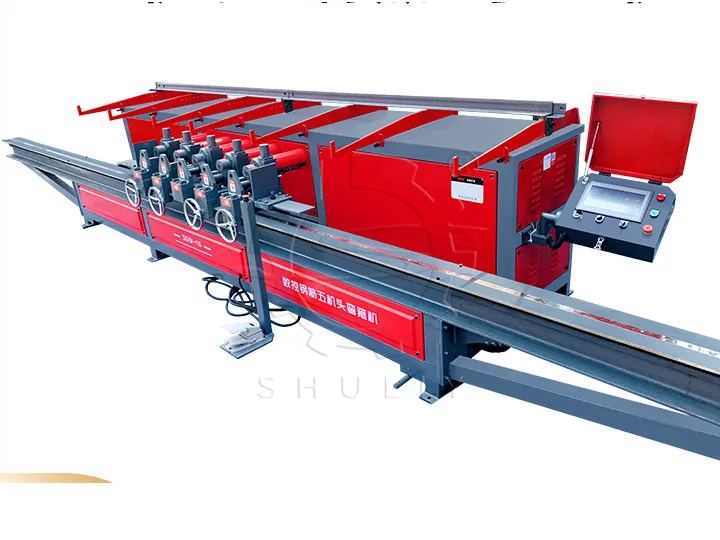

- Conception modulaireDes machines telles que le coupe-latéral de pneus, le coupe-bande, le coupe-bloc, le séparateur de fil d'acier, le déchiqueteur, le système de broyage et de séparation magnétique, et le séparateur de fibres peuvent être configurées individuellement ou comme une ligne complète.

- Construction Durable: Les pièces clés sont fabriquées à partir de matériaux résistants à l'usure comme le 5Cr6MnMo, garantissant une longue durée de vie et une réduction de l'entretien.

- Faible Exigence de Main-d'œuvre: Fonctionnement simple avec seulement 2 à 4 travailleurs nécessaires pour la production quotidienne.

- Efficace en Énergie: Consomme 30 % d'énergie en moins par rapport aux équipements de recyclage de pneus traditionnels, réduisant ainsi les coûts opérationnels.

- Empreinte Compacte: Agencement compact, facile à installer et à entretenir.

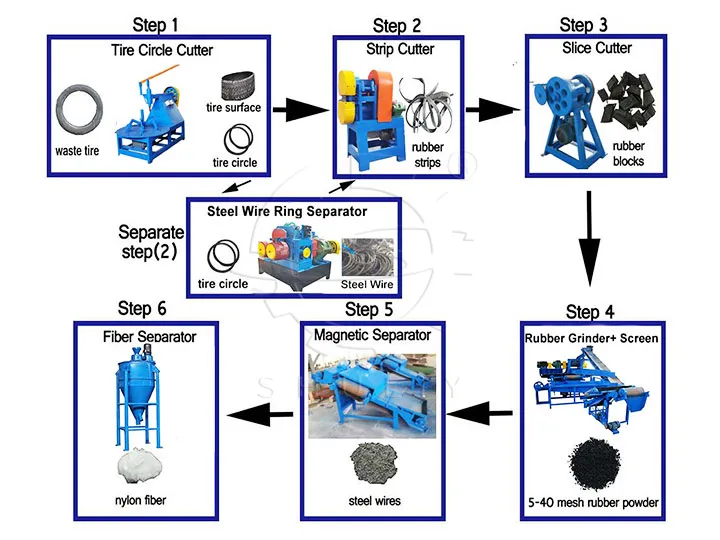

Processus de Travail de l'usine de recyclage de pneus usagés

Processus complet d'une usine de recyclage de pneus usagés semi-automatisée : coupeuse de flanc de pneu → coupeuse de bandes de pneu → coupeuse de blocs de pneu → séparateur de fil d'acier de pneu → broyeur de pneus et séparateurs magnétiques → séparateur de fibres

Prétraitement : Le coupe-latéral de pneu retire les jantes en acier intégrées au talon du pneu. Ensuite, le coupe-bande et le coupe-bloc découpent le flanc du pneu en bandes de 3 à 5 cm de large et en blocs de 5*5 cm à tour de rôle.

Séparation des fils d'acier : Le séparateur de fils d'acier sépare efficacement le caoutchouc du fil de talon pour un recyclage classé. Cette machine est optionnelle dans l'usine de recyclage semi-automatique de pneus usagés.

Broyage et criblage : Grâce au processus de la machine de broyage de pneus et des cribles, elle peut produire de la poudre de caoutchouc dans des tailles prédéfinies.

Élimination des impuretés : Les séparateurs magnétiques à plusieurs étapes et le séparateur de fibres sont conçus pour éliminer les éléments magnétiques et les fibres. Enfin, ils peuvent produire des poudres de caoutchouc fines avec une pureté de plus de 99 %, qui peuvent être utilisées dans la fabrication industrielle.

Coût d'une usine de recyclage de pneus usagés

Mettre en place une usine de recyclage de pneus usagés est une activité rentable et durable, car la demande mondiale de caoutchouc recyclé continue de croître.

Pour démarrer une entreprise de recyclage de pneus, vous devez prévoir le budget suivant :

- Coût de la machine: Une ligne semi-automatique avec coupeur de flanc de pneu, broyeur, etc., à partir de $24490, selon la capacité.

- Espace d'usine: Le coût de location ou de construction varie selon l'emplacement.

- Matières premières: Les pneus usagés sont généralement sourcés localement ; le stock initial peut nécessiter 1 000 $ à 5 000 $.

- Main-d'œuvre: Besoin uniquement de 2 à 4 travailleurs; les salaires mensuels dépendent des tarifs locaux.

- Électricité: Produire 1 tonne de poudre de caoutchouc consomme 150–180 kWh, ce qui aide à économiser sur les factures d'énergie.

- Maintenance et pièces d'usure: Coût faible en raison de matériaux durables comme le 5Cr6MnMo.

- Expédition et installation: Varie selon le pays, généralement 2 000 $–8 000 $.

Chez Shuliy, nous proposons des solutions de recyclage sur mesure pour vous aider à réduire vos coûts d'investissement et de fonctionnement. Que vous souhaitiez produire des granulés de caoutchouc ou gérer une ligne de production de poudre de caoutchouc complète, notre équipement est fiable, peu encombrant et économe en énergie.

Contactez-nous pour obtenir un plan d'usine personnalisé et un devis !