À mesure que l'économie augmente et que la conscience de l'environnement augmente, la demande du marché en plastique recyclé augmente. Le film plastique, un type commun de plastique, offre une valeur de recyclage considérable.

L'utilisation de machines avancées de recyclage PP transforme les déchets plastiques en granulés recyclés de haute qualité, bénéficiant aux entreprises économiquement tout en augmentant votre image environnementale et votre compétitivité du marché.

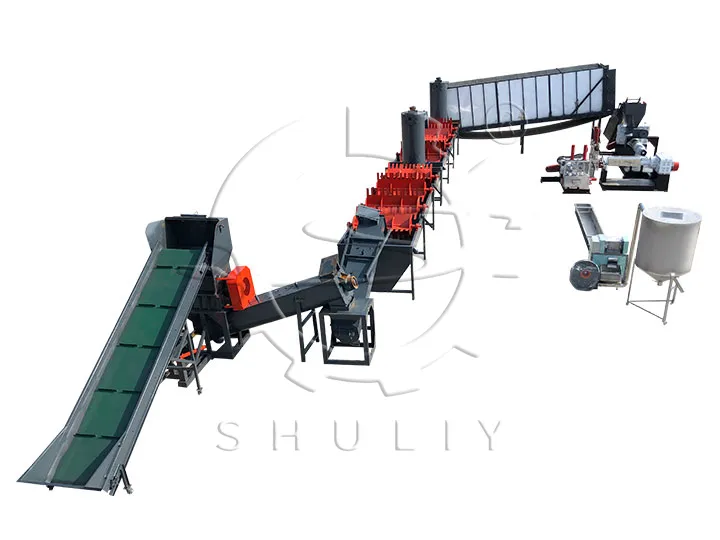

Détails de nos machines de recyclage de film PP PE

Avec des technologies de déchiquetage, de lavage et de granulation de premier plan, nous avons créé une chaîne de production complète pour le recyclage des films plastiques qui atteint une production efficace et une excellente qualité de granules recyclés.

Nos machines de recyclage de films PP PE ont un large éventail d'applications, non seulement pour les films plastiques PP PE mais aussi pour les LDPE, PET, etc. Qu'il s'agisse de films plastiques post-consommation ou post-industriels, ils peuvent être transformés en granulés de haute qualité pour une utilisation dans la construction, le médical, l'emballage et d'autres applications. La capacité de 100-500 kg/h peut satisfaire la plupart des recycleurs de films plastiques. Si vous avez d'autres besoins, veuillez nous laisser un message pour nous contacter, nous pouvons vous fournir des machines de recyclage de films PE personnalisées.

Comment notre ligne de recyclage de films plastiques stimule-t-elle votre entreprise de recyclage?

Transformer les déchets en bénéfices

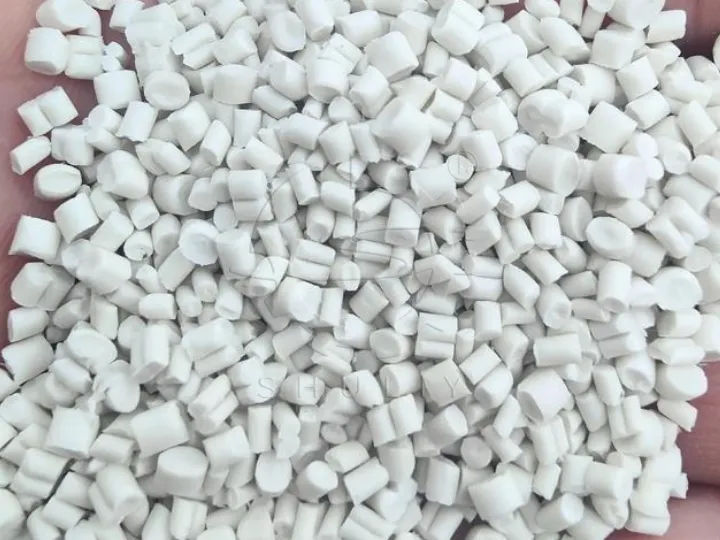

Les déchets en plastique sont recyclés à l'aide d'une machine de recyclage de film PE qui la convertit en pastilles en plastique recyclé de haute qualité. Si vous êtes un recycleur en plastique, vous pouvez vendre les pastilles aux fabricants qui ont besoin de plastiques recyclés et réaliser un profit, ou si vous êtes un fabricant en plastique, vous pouvez réduire vos coûts de matières premières par recyclage post-industriel dans votre industrie.

Améliorez votre efficacité de recyclage en plastique

Nous pouvons vous fournir un ensemble complet de solutions de recyclage personnalisées, y compris un broyeur de sacs en plastique, une laveuse de déchets plastiques, une granulatrice de films PP PE, un séchoir à plastique, etc. Adoptant une technologie avancée et des matériaux de haute qualité, nos machines de recyclage de films PE sont plus efficaces et durables que les machines du même type sur le marché. De plus, les granulés de plastique produits sont de meilleure qualité : uniformes et pleins, performances stables, haute pureté, sans pollution et sans adhérence !

Réduire la consommation d'énergie

Nos machines de recyclage de films PE sont conçues pour être économe en énergie et réduire les coûts d'exploitation. Par exemple, la ligne de lavage LDPE est équipée d'un système de recyclage de l'eau pour éviter de gaspiller les ressources; La machine d'extrudeuse de recyclage en plastique peut choisir le chauffage électromagnétique, qui est rapide et évite la perte de chaleur.

Accès à l'assistance des politiques

Ces dernières années, plusieurs pays et régions ont encouragé les investissements dans l'industrie du recyclage des plastiques par le biais de politiques gouvernementales et de soutien financier. La participation active au recyclage des films plastiques contribue non seulement à la protection de l'environnement et améliore l'image verte d'une entreprise, mais peut également entraîner un soutien financier ou des incitations fiscales.

Par exemple, des pays comme le Kenya et le Nigéria ont promulgué ou sont en train de promulguer des interdictions de produits plastiques pour réduire la pollution plastique et favoriser le recyclage du plastique. En participant à des programmes de recyclage en plastique, les entreprises peuvent non seulement répondre à la demande croissante du marché, mais également réduire les risques juridiques et profiter des dividendes du soutien politique.

Cas réussis de la ligne de production en plastique en plastique Shuliy

En tant que fournisseur de premier plan de machines de recyclage en plastique, nous avons aidé les clients dans de nombreux pays à établir des systèmes de recyclage en plastique et en récolter les avantages économiques. Voici quelques-unes de nos études de cas à lire si vous êtes intéressé.

- Grande machine de fabrication de granulés de plastique au Ghana

- Machine de fabrication de granulés de plastique à vendre au Kenya

- Granulateur de recyclage de film plastique pour l'Allemagne

Conclusion

En investissant dans des machines de recyclage de films par PP PP, vous serez en mesure de traiter efficacement une large gamme de matières premières, d'augmenter l'efficacité du recyclage et de réduire les coûts d'exploitation. Nous proposons également des services tels qu'une garantie gratuite d'un an et un support de pièces à vie.

Commandez aujourd'hui et commencez à économiser! Pour nous contacter, cliquez sur le bouton sur le côté droit de l'écran!