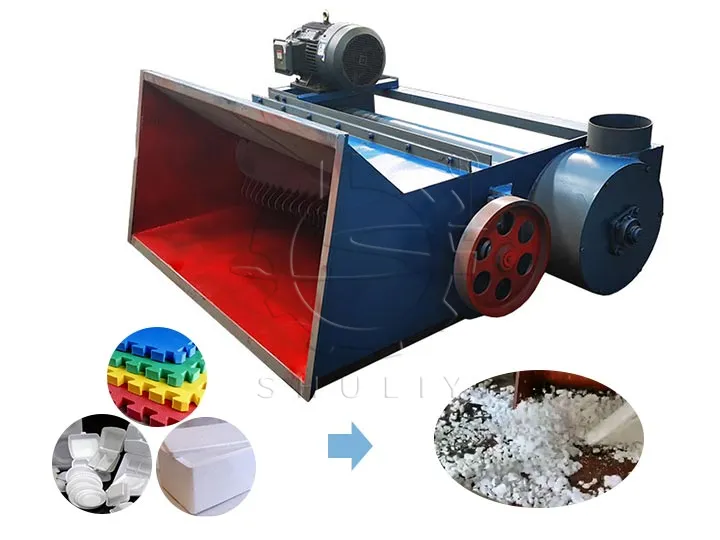

Foam crushing machine is a machine used to recycle waste styrofoam. The workflow of the PU foam shredder machine includes the process of choosing the right equipment, pre-processing, and crushing.

Choosing the right foam crushing machine

The first step in foam crushing is to choose the proper small foam shredding machine. Shuliy has SL-800, SL-100, SL-1200, and SL-1500 models of foam crushing machines. The output of different models of PU foam shredder machines is different.

You can choose the PU foam shredder machine according to the amount of foam you want to process every day. In addition, you should also consider the inlet size of the small foam shredding machine, machine power, foam material, and so on.

Pre-processing Foam

Before foam crushing, the foam material needs to be pretreated to speed up the crushing efficiency. Pretreatment methods include both cooling and compression.

Cooling the foam material in a low-temperature environment reduces the elasticity of the foam, making it easier to crush. Compressing the foam material to increase the density of the foam material makes the crushing effect better.

Beginning to crush foam

Put the foam material into the foam crushing machine. Adjust the rotating speed of the equipment and the blades of the crusher and start crushing.

During the crushing process, you should pay attention to observing the crushing effect and the operation status of the equipment. Once the PU foam shredder machine is faulty, it should be shut down in time to deal with it.