Foam compactor machines, also known as foam compression machines, can reduce the volume of polystyrene foam exponentially. Best styrofoam compactor processes foam without heat throughout the entire process. It can be said that the EPS styrofoam recycling compactor is a rare economical and environmentally friendly product in foam recycling equipment.

How does foam compactor machine work?

In use, the operator simply drops the foam into the hopper and the foam compactor machine will break up the foam through its own shredding section. Next, the foam is screw-compressed to form square foam compression blocks.

If your foam is too large, it is recommended to crush it with a foam shredder before compressing it.

The EPS foam compactor effectively solves the problem of EPS, EPP, EPE foam, and polyurethane foam recycling difficulty and transportation inconvenience. Shuliy best styrofoam compactor has a high compression ratio and no odor in the cold pressing process.

How about best styrofoam compactor cost?

The styrofoam compactor cost is low and it is an ideal foam recycling machine. We have a choice of foam compression machines with outputs of 400kg/h, 600kg/h, 800kg/h, and 1000kg/h. EPS styrofoam recycling compactors with other outputs can be made according to your needs. You can leave a message on the website if you need other output foam compactor machines.

Advantages of EPS foam compactor

- Foam compression ratio up to 40:1.

- High density of the compacted foam.

- Compacted foam blocks are easy to truncate, store, and stack.

- Shuliy EPS styrofoam recycling compactor has a crushing structure.

- Low energy consumption and no odor from the cold pressing process.

- The size of the feed opening and discharge length can be adjusted.

- Foam compactor machine price is reasonable.

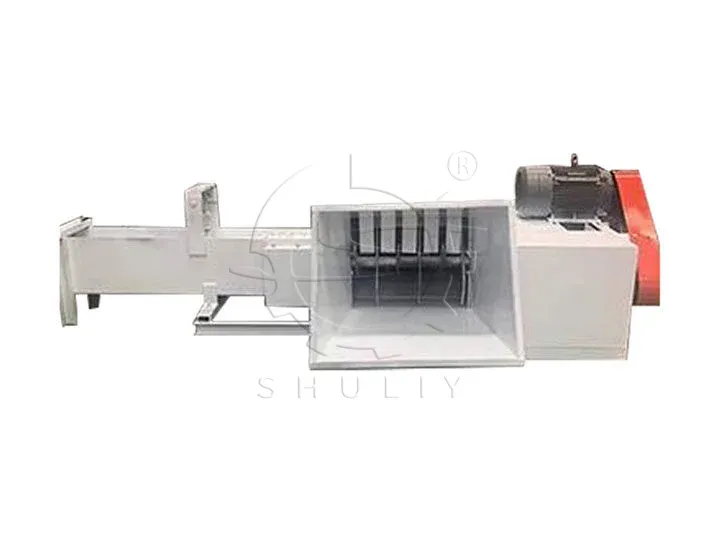

Two types of foam compression machine

Shuliy has two types of EPS styrofoam recycling compactors to choose from. One is horizontal and the other is vertical. The difference between them is the different feeding methods. Horizontal foam compression machine has a bottom feed and vertical foam compactor machine has a top feed.

Generally speaking, bottom-feeding is more convenient and is suitable for factories with larger production capacities. Vertical EPS styrofoam recycling compactor can be equipped with a conveyor belt to achieve the effect of continuous feeding.

EPS styrofoam recycling compactor parameters

| Model | SL-260 | SL-350 | SL-400 |

| Power(kw) | 7.5 | 11 | 15 |

| Compression ratio | 40:01:00 | 40:01:00 | 40:01:00 |

| Input size(mm) | 600*800*1400 | 800*900*1400 | 800*900*1600 |

| Capacity(kg/h) | 600 | 800 | 1200 |