La línea de reciclaje de neumáticos desechados totalmente automática está diseñada para procesar neumáticos de hasta 1200 mm de diámetro. Produce y separa de manera eficiente polvo de caucho (con una pureza de al menos 99%), llantas y fibras para su reutilización. Con una baja inversión y altos retornos, este proyecto ofrece una oportunidad de negocio rentable y sostenible!

materias primas y productos finales

Materias primas

Todos los neumáticos con un diámetro inferior a 1200 mm pueden ser reciclados por líneas de reciclaje de neumáticos desechados totalmente automáticas, incluyendo: neumáticos de automóviles, neumáticos de camiones, neumáticos de autobuses, etc. Nuestra línea de producción de reciclaje de neumáticos es ideal para plantas de reciclaje de neumáticos, fabricantes de polvo de caucho y empresas que buscan reducir los desechos de neumáticos y generar beneficios a partir de materiales reciclables.

Productos finales

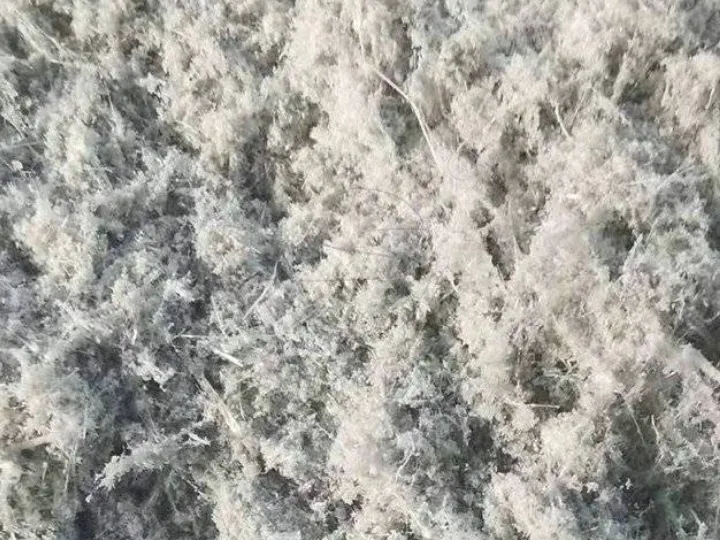

Estos neumáticos desechados contienen recursos valiosos como caucho, alambre de acero, negro de carbón, fibra, etc. Al reciclar, puedes convertir desechos en tesoros y obtener:

- polvo de goma de malla 10-40 con pureza ≥99%

- Aros de acero para la fabricación de acero nuevo

- Las fibras se pueden utilizar como combustible o material de acolchado

¿Por qué la línea de reciclaje de neumáticos desechados de Shuliy lidera el mercado?

- Alto grado de automatización: Eficiente y ahorro de mano de obra.

- Se adapta a las necesidades de producción: Existen diversas soluciones de reciclaje.

- Flexible: Control en tiempo real y seguimiento del progreso de producción. El tamaño de las partículas del polvo de caucho se puede ajustar a un rango de 10-40 mallas.

- Productos finales de alta calidad: La producción de polvo de caucho de alta pureza (≥99%), alambre de acero y fibra se puede reutilizar directamente en la industria para su reutilización o venta.

- Ahorra energíaAdopta un diseño que ahorra energía que reduce en 1/3 la energía consumida por las máquinas tradicionales de polvo de goma.

- Servicio perfecto: Personal experimentado proporciona personalización de máquinas, planificación del sitio, instalación en el lugar, orientación técnica y una garantía gratuita de un año.

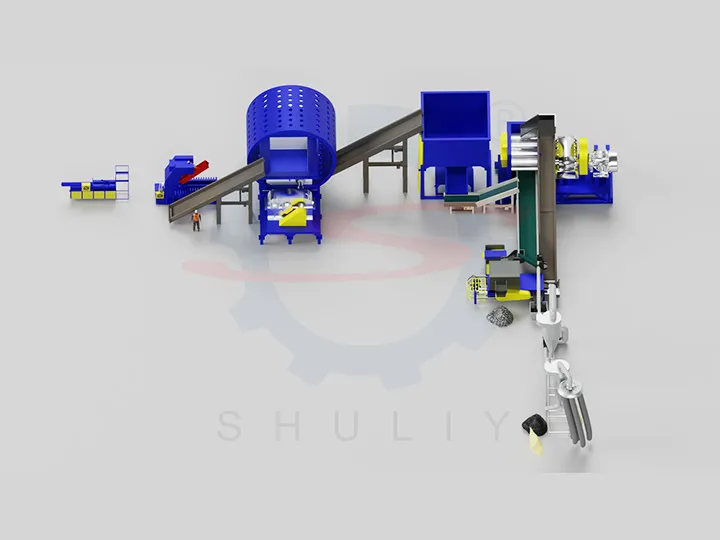

3 tipos de plantas de reciclaje de neumáticos usados

Línea de desmonte y corte de neumáticos

La primera línea de reciclaje de neumáticos usados consiste en un desollador de neumáticos, un cortador de neumáticos, una máquina de triturado de neumáticos, un sistema de molienda y tamizado de neumáticos, y un separador de fibras.

Proceso de trabajo:

- Máquina de desmonte de neumáticos: Impulsada por un potente sistema hidráulico, elimina eficientemente los bordes de los neumáticos.

- Máquina de corte de neumáticos: Corta neumáticos en secciones que se pueden introducir fácilmente en una trituradora de caucho.

- Trituradora de neumáticos: Tritura eficientemente neumáticos y produce bloques de goma de 50-100 mm. La capacidad de la máquina es de 2-20 t/h, y hay disponibles varios modelos.

- Sistema de molienda y tamizado de neumáticos: Rodillos dobles hechos de 5Cr6MnMo muelen piezas de neumáticos y producen polvo de goma de alta pureza de un tamaño establecido, que varía de 10 a 40 mallas, a través de un tamizado en múltiples etapas y separadores magnéticos.

- Separador de fibra: Elimina eficazmente las fibras de los polvos de caucho.

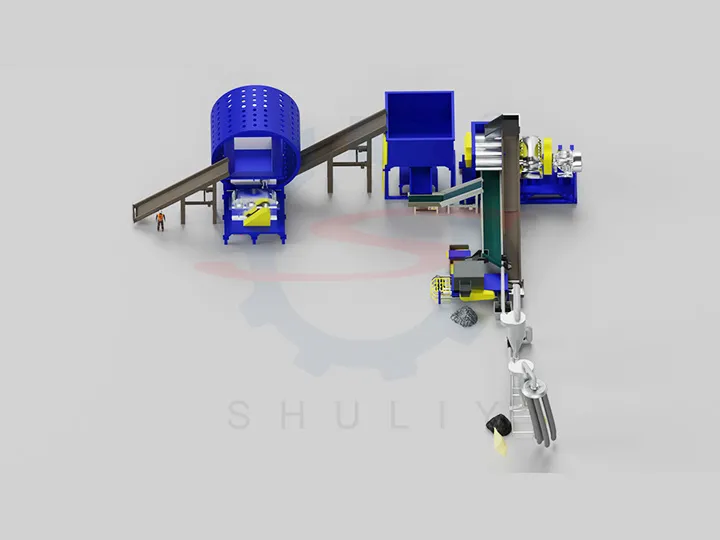

Línea de desmontaje de neumáticos y separación de alambres

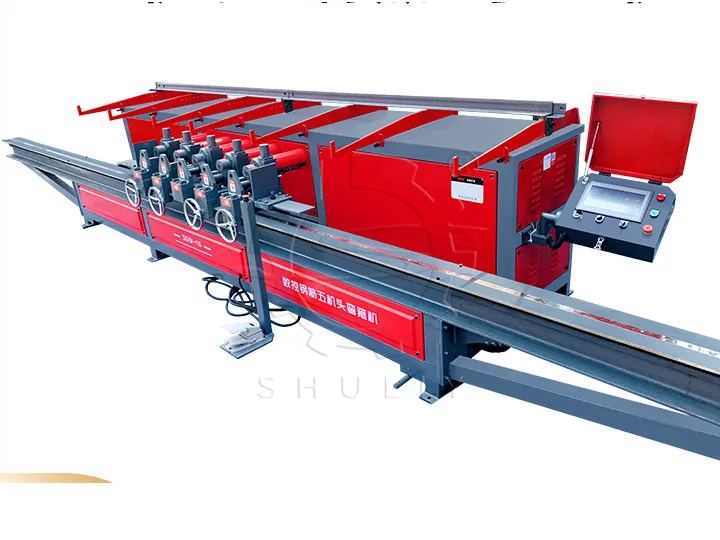

Esta segunda línea de producción de polvo de caucho incluye: máquina removedora y cortadora de talones de neumáticos + separador de alambre de acero de neumáticos + trituradora de neumáticos + trituradoras de neumáticos y separadores magnéticos

Proceso de trabajo:

- Máquina removedora y cortadora de bordes de neumáticos: Elimina eficientemente los bordes de los neumáticos y corta los neumáticos en piezas.

- Separador de alambre de acero para neumáticos: Tritura las perlas y separa y elimina de manera efectiva los alambres de acero incrustados.

- Trituradora de neumáticos: Tritura neumáticos de goma en piezas uniformes.

- Unidad de molienda y tamizado de neumáticos: Muele y tamiza, eliminando impurezas y produciendo polvo de goma.

- Separador de fibras: Eliminar impurezas de fibra.

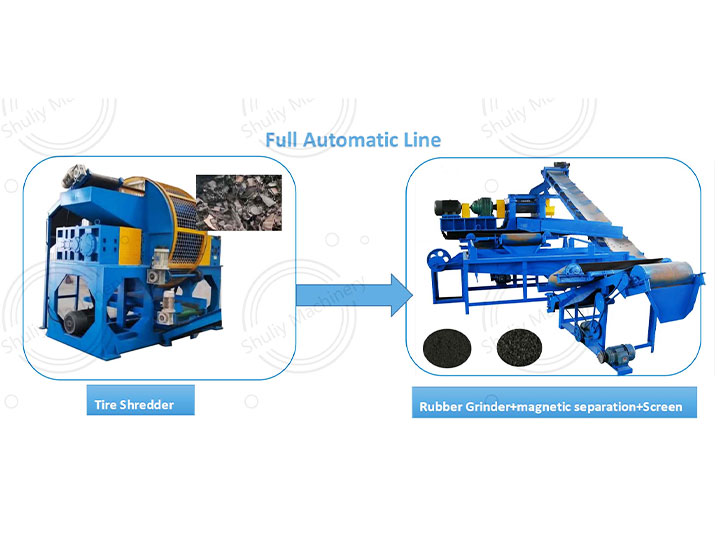

Línea de reciclaje de neumáticos por triturado directo

Para trituradoras de neumáticos de modelo 1200 en adelante, debido a su alta potencia y robusto sistema de trituración, puedes elegir directamente la tercera solución: Trituradora de neumáticos + molino de goma y separador magnético + separador de fibra. Funcionan de la misma manera que se mencionó anteriormente.

Reciclar neumáticos de desecho con maquinaria Shuliy

A medida que la industria automotriz se desarrolla y la demanda de caucho reciclado crece, el reciclaje de neumáticos desechados se está convirtiendo en un proyecto sostenible y rentable. Este proceso reduce los desechos en vertederos y la carga ambiental, al mismo tiempo que recicla y reutiliza recursos. Si estás interesado, contáctanos para saber más sobre nuestras soluciones personalizadas de reciclaje de neumáticos, que ofrecen una baja inversión y un alto retorno.