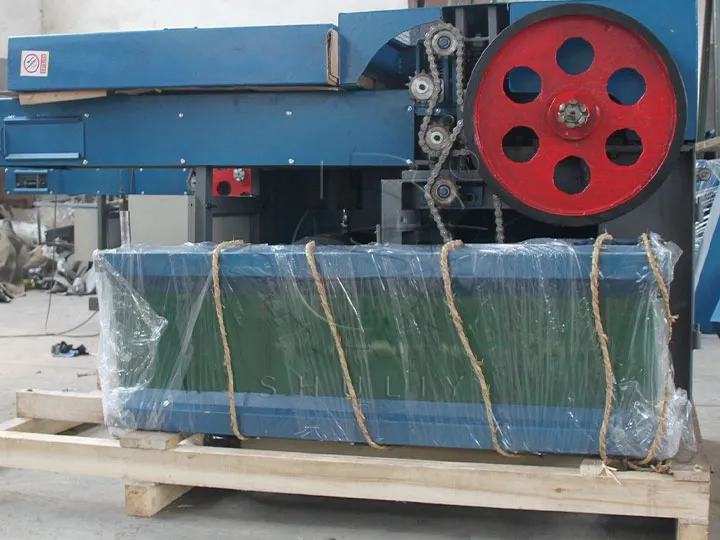

La máquina de corte de fibra (también conocida como máquina de corte de desechos de algodón o trituradora textil) es un cortador industrial especialmente diseñado para procesar materiales de desecho suaves y fibrosos en piezas cortas para su reciclaje. Ya sea que esté en las industrias textil, plástica o no tejida, nuestro cortador de tela ofrece cortes limpios y de longitud ajustable para reciclaje o procesamiento secundario.

De residuos textiles a piezas más pequeñas

Esta máquina puede triturar una amplia gama de materiales blandos, lo que la convierte en una pieza clave de equipo para los procesos de reciclaje en muchas industrias:

- Residuos textiles: hilo de algodón, ropa vieja, denim, poliéster

- Película plástica: película agrícola, película de embalaje, bolsas tejidas

- Tela no tejida y fieltroresiduos de producción en el borde

- recortes de espuma y cuerode fábricas de colchones y muebles

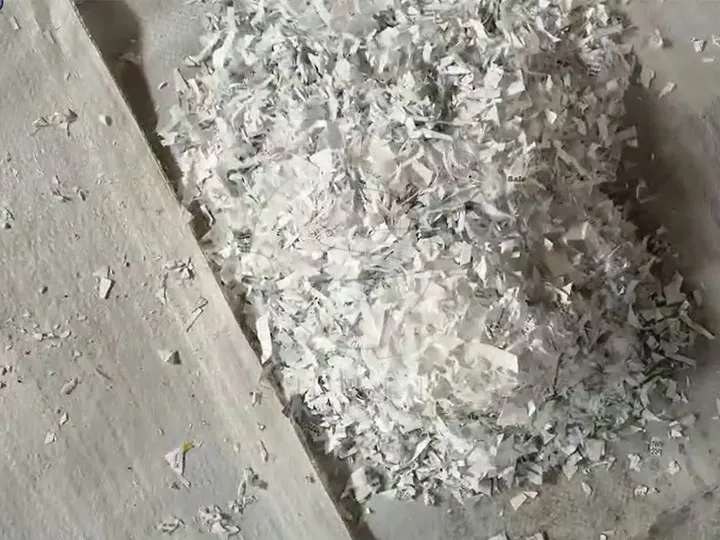

- papel y etiquetasresiduos de recorte de líneas de impresión o embalaje

🔄 Producto final: piezas de fibra uniformes (ajustables de 5mm a 300mm), ideales para los procesos posteriores como la apertura y el aflojamiento.

Características clave de nuestra máquina de corte de fibra de tela

- Diseño de cuchilla rotativaPermite un corte continuo y de alta velocidad

- Tamaño de corte ajustable: La longitud de corte varía de 5 mm a 300 mm (disponible con engranaje continuo o fijo)

- Cuchillas de acero de aleación: Bisel de corte duradero y preciso

- Sistema de doble motor: Motores separados para la alimentación y el corte para un funcionamiento estable

- Gabinete de control independiente: Incluye protección contra sobrecargas, parada de emergencia y soporte de inversor

- Separador Magnético Opcional: Previene que los desechos metálicos dañen las cuchillas

- Cintas Transportadoras Anchas: Asegura una alimentación y salida suaves con menos mano de obra

Especificaciones técnicas de la máquina de corte de tela de desecho

Si tiene otras necesidades de producción, ¡no dude en contactarnos! Podemos proporcionarle máquinas de corte de fibra textil personalizadas.

| Modelo | Capacidad | Potencia del motor | Tamaño de Corte | Ancho de Entrada/Salida | Grosor de corte |

|---|---|---|---|---|---|

| 500B | 300–500 kg/h | 5.5 + 1.5 kW | 5–150 mm | 2800*350 mm | 20 mm |

| 800C | 500–800 kg/h | 7.5 + 1.5 kW | 5–150 mm | 2800*350 mm | 30–50 mm |

| 1200B | 800–1200 kg/h | 15 + 2.2 kW | 5–150 mm | 3000*520 mm | 30–50 mm |

| 1600B | 1000–3000 kg/h | 18.5 + 3.0 kW | 5–300 mm | 3000*720 mm | 30–150 mm |

| 2400B | 2000–5000 kg/h | 22 + 3.0 kW | 10–300 mm | 3000*1100 mm | 30–200 mm |

¿cómo funciona la máquina de corte de desechos de tela?

- El material se coloca en la amplia cinta de entrada

- Los rodillos de presión aseguran una alimentación compacta

- Las cuchillas rotativas cortan el material en piezas uniformes

- La cinta de salida transporta automáticamente el producto terminado

Este diseño permite un procesamiento continuo de corte ajustable en longitud, eficiente y con bajo requerimiento de mano de obra. Las piezas cortadas de fibras de fibra pueden ser abiertas y aflojadas.

Caso Real: Fábrica de No Tejidos en Brasil – Aumento de Productividad de 3x

Un cliente en Brasil que produce telas no tejidas estaba cortando manualmente los desechos de producción con un equipo de 8 personas. Después de instalar nuestra máquina de corte de fibra SL-1600B personalizada, ellos:

- Reducción de mano de obra a solo 1 operador

- Producción diaria triplicada de 800 kg a más de 2.5 toneladas

- Se logró una producción uniforme compatible con su línea de reciclaje de telas desechadas.

“¡Muy eficiente! Ahorramos mano de obra y duplicamos la producción.” – Cliente de Brasil

Precio de la máquina de corte de desechos de algodón

¿Buscas ampliar tu línea de reciclaje con una máquina cortadora de fibra confiable y de grado industrial? Contáctanos ahora para asesoramiento experto y una cotización. También ofrecemos otros equipos de reciclaje de fibra, como abrelatas de fibra.

📞 WhatsApp: +86 17303831295

📧 Correo electrónico: info@shuliyrecycle.com