Las máquinas de reciclaje de neumáticos OTR tienen una demanda creciente a medida que las industrias minera y de servicio pesado se expanden. Los neumáticos fuera de uso (OTR), a menudo de más de 2 metros de ancho y que pesan varias toneladas, son demasiado grandes y resistentes para los sistemas de reciclaje estándar. Para hacer frente a este desafío, Shuliy Machinery ofrece dos soluciones de alta eficiencia adaptadas a neumáticos de gran tamaño de camiones mineros, cargadores y otros vehículos de servicio pesado.

Materias primas para el reciclaje de neumáticos OTR

Nuestra línea de reciclaje de neumáticos OTR está diseñada específicamente para manejar neumáticos grandes y resistentes ≥1400 mm, incluyendo:

- Neumáticos de camiones de minería gigantes

- Neumáticos de cargadoras y bulldozers

- Neumáticos OTR agrícolas

- Neumáticos OTR desechados con diámetros de llanta que superan las 25 pulgadas

Productos finales y sus aplicaciones

La línea de reciclaje de neumáticos OTR puede producir:

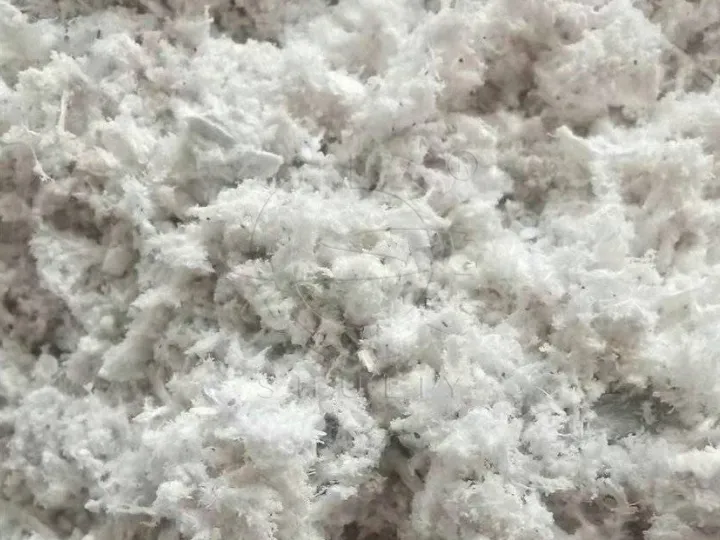

- Gránulos de caucho y Caucho triturado: Utilizados en pavimentación de carreteras, alfombrillas de goma, pistas deportivas, etc.

- Alambre de acero recicladoVendido como chatarra para fundición y reutilización.

- Materiales de fibra: Utilizados como aditivos o rellenos en otros procesos industriales.

Características clave de las máquinas de reciclaje de neumáticos OTR

- Diseño resistente: Construidos para cargas de trabajo extremas, capaces de manejar neumáticos de 1.4 a 4 metros de diámetro.

- Alta eficiencia: Sistemas integrados que reducen la mano de obra y el tiempo de procesamiento.

- Tamaños de salida ajustables: La producción final de goma puede variar desde chips de goma hasta goma triturada (0.63–5 mm), adecuada para diversas aplicaciones.

- Separación de acero y fibra: Logra una separación de alta pureza (pureza del polvo de goma >99%), maximizando el valor del material.

- Ahorro de energía y duradero: Utiliza materiales resistentes al desgaste y controles inteligentes para reducir los costos de energía y extender la vida útil.

Las dos soluciones personalizadas de reciclaje de neumáticos OTR de Shuliy

Para satisfacer las diversas necesidades de las plantas de reciclaje globales, Shuliy ofrece dos configuraciones prácticas:

Línea de corte y separación tradicional

Para neumáticos OTR de 1400-4000 mm

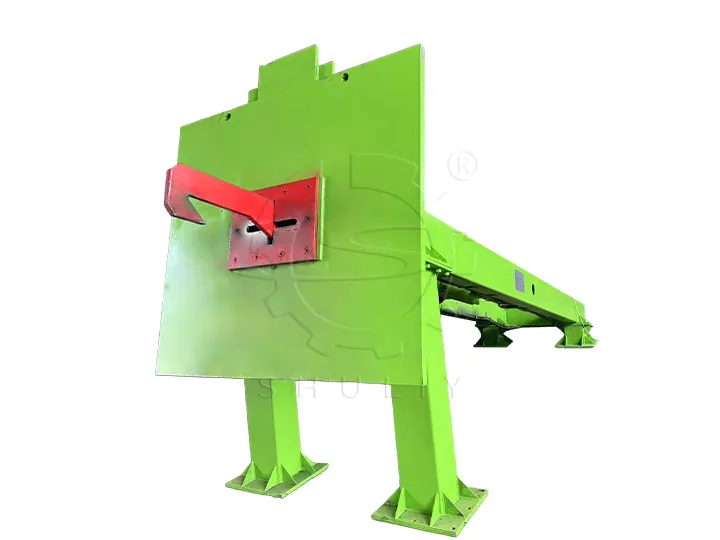

- Desmontadora de neumáticos OTR: Elimina el alambre de acero del neumático OTR.

- Máquina de corte de neumáticos OTR: Corta el neumático grande en piezas manejables.

- Trituradora de neumáticos: Tritura neumáticos cortados en trozos de goma más pequeños.

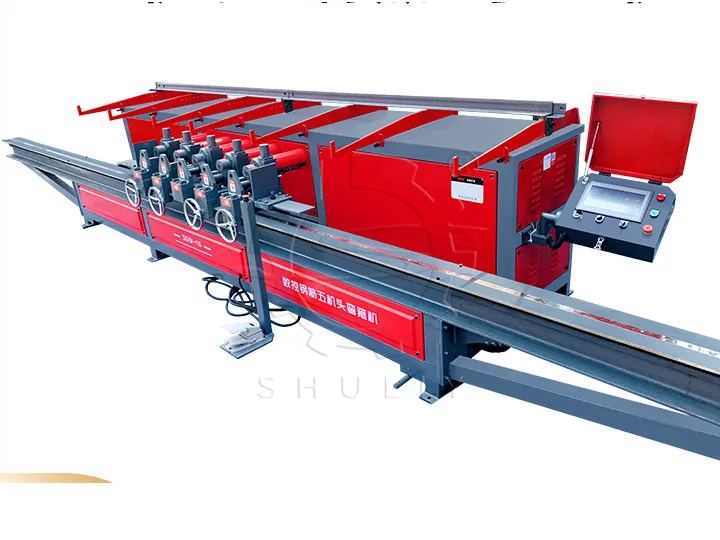

- Molino de neumáticos y separación magnética: Tritura goma en polvo de goma y separa alambres de acero fino.

- Separador de fibras: Elimina la fibra textil restante para garantizar la pureza del producto.

Línea de trituración y desmantelamiento eficiente

Adecuado para neumáticos OTR gigantes con un diámetro de 2100 mm o más

- Desmontadora de neumáticos OTR: Separa mecánicamente la banda de rodadura, los flancos, etc. de los grandes neumáticos OTR.

- Separador de alambre de acero: Extrae además componentes de acero incrustados del talón del neumático. Luego, coloca la parte de goma en la trituradora de neumáticos.

- Trituradora de neumáticos y molino con sistemas de separación magnética y de fibra.

Ambas soluciones están diseñadas para operación continua y pueden personalizarse para adaptarse a diferentes capacidades de producción.

Parámetros de nuestras máquinas de reciclaje de neumáticos oTR

| Nombre | línea de reciclaje de neumáticos OTR |

| Materias primas | Todos los neumáticos gigantes de más de 1400 mm de diámetro |

| Productos finales | Polvos de goma fina |

| Productos secundarios | Cables y fibras de acero |

| Tamaño del polvo de caucho | 10-40 mallas |

| Pureza del polvo de caucho | más del 99% |

| Garantía | Una garantía gratuita de un año |

¿Por qué elegir las máquinas de reciclaje de neumáticos de minería de Shuliy?

Shuliy tiene más de 10 años de experiencia en la fabricación de equipos de reciclaje. Nuestras soluciones de reciclaje de neumáticos OTR son confiables para sitios mineros y plantas de reciclaje en todo el mundo por su fiabilidad, rendimiento y rentabilidad. Proporcionamos:

- Diseño de planta personalizado

- Guía de instalación

- Capacitación técnica

- Soporte postventa y repuestos

📩 Contáctenos hoy para obtener un presupuesto personalizado y comenzar a construir su planta de reciclaje de neumáticos OTR.