EPS granulator is mainly used to process waste fast food boxes, home appliance packaging EPS foam reuse. EPS recycled granules can be used to manufacture exterior wall insulation boards, all kinds of stationery, toys, electrical appliance shells, and so on.

How to make EPS granules with EPS granulators?

The principle of the EPS pelletizing machine is to drive the reducer through the motor so that the material is constantly pushed forward. The foam melts under the action of the heating device of the EPS pelletizer. Then the foam is turned into recycled pellets through extrusion, cooling, cutting, and other processes.

EPS pelletizing machine applications

EPS granulators can process foam boxes, foam fillers, foam boards, packaging foam, and so on. Common foam in daily life can be processed by this EPS granules making machine.

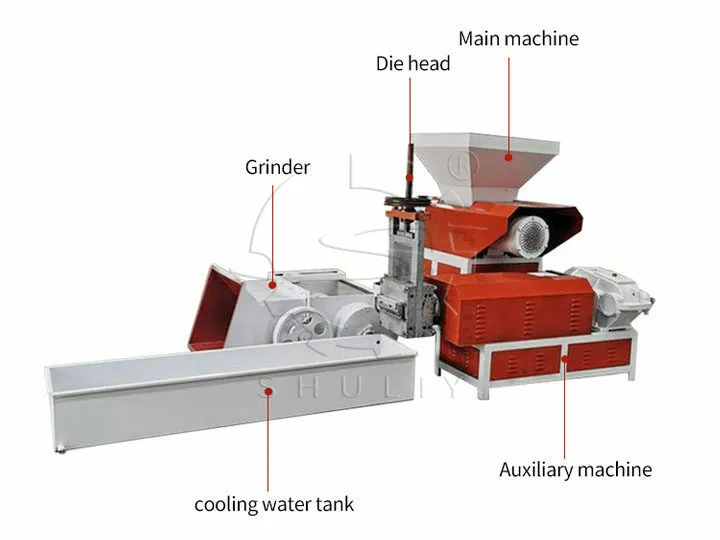

Structure of EPS granules making machine

EPS granulator needs to be used with a foam crush machine, cooling tanks, and EPS pellet cutter to complete the production of plastic pellets. This picture below shows the main structure of the EPS pelletizer.

What are EPS pelletizer parameters?

| Model | Capacity (KG/H) | Main motor (KW) |

| SL-220 | 150-175 | 15 |

| SL-270 | 200-225 | 18.5 |

| SL-320 | 275-300 | 18.5 |

| SL-370 | 325-375 | 22 |

Shuliy EPS granulator can be equipped with double reducers or single reducers. The configuration of the EPS foam granules machine can be adjusted according to the customer’s requirements.

How to adjust the temperature of plastic EPS pelletizing machine?

EPS pelletizing machine needs to work under the proper temperature to achieve the best granulation effect. The temperature adjustment of the EPS granulator can be divided into three steps:

- Pre-heating stage: It is recommended to preheat the foam at about 140℃-150℃.

- Melt stage: The preheated foam will be fed into the foam granulator auxiliary machine, and it is recommended to be regulated at about 170℃-180℃.

- Cooling stage: Cool the molten foam into granules, it is recommended to be adjusted around 80℃-100℃.

Value of EPS granules

EPS pellets produced by Shuliy Foam GranulatEPS granules making machine or can be used for the following applications:

- As stuffing material for furniture, toys, garbage cans

- Heat-insulating material used in construction, automobiles, and other fields.

- Recycled EPS granules can be used in the field of manufacturing packaging, for example, to fill boxes or as filler material used when mailing parcels.