EPS

The full name is Expanded Polystyrene and its recycling process is moderately difficult.

Characteristic:

As a common type of waste, EPS foam plastic has lightweight, fragile, and space-consuming characteristics, often used in packaging and building insulation boards.

Challenges:

Due to its fragile nature, EPS will shed many tiny particles during recycling, making it difficult to clean and separate. Additionally, adhesives and other impurities attached to the EPS foam plastic also require special treatment.

Appropriate Equipment:

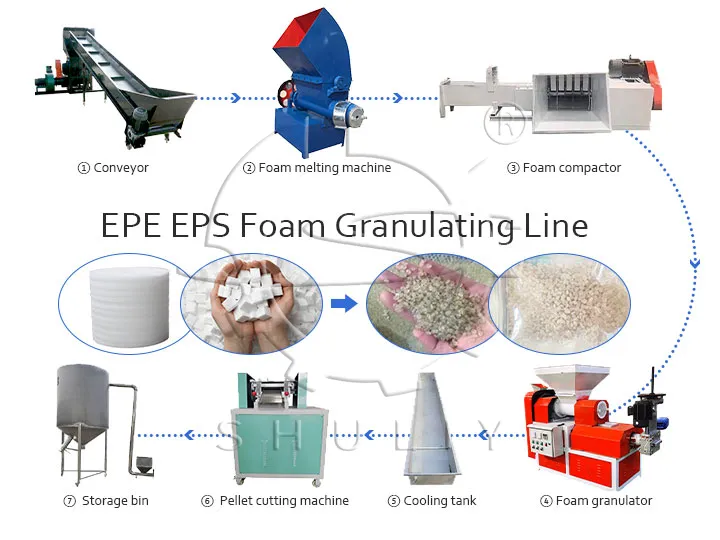

- Cold Compressing Machine: It is a crucial component in foam recycling to compact large foam plastics into dense ingots and the compression ratio is 40:1, which makes it easier to transport and store.

- Hot melting machine: EPS hot melting recycling machine crushes and melts EPS foam, and finally converts it into lumps to facilitate subsequent recycling.

- EPS pellet cutting machine: Crushing foam plastics into uniform pellets in size and shape as required, which can be used in the reproduction line.

EPE

EPE stands for Expanded Polyethylene with a low to medium recycling difficulty.

Characteristic:

Like EPS, it is lightweight. However, EPE is more flexible and has a higher density, making it easy to shape and commonly used as protective packaging material, such as for electronic products.

Challenges:

It’s easier to recycle but care should be taken to avoid EPE materials becoming entangled with the machine during melting and crushing, which can cause the machine to malfunction.

Appropriate Equipment:

- Plastic Foam Crusher: Crushing large foam products into small pieces for subsequent recycling.

- Foam Plastic Compactor: Compress foam pieces into tight blocks to make it easy to melt and extrude.

- Hot Melting Machine: Heats and melts plastic granules into a molten state and then extrudes them into the shape of long strips.

- Cutting Machine: After cooling, the plastic foam cutting machine cuts long strips into reuse pellets.

XPS

XPS is also known as extruded polystyrene, and it is more difficult to recycle.

Characteristic:

It has high strength, high density, and low water absorption rate, and is often used in construction and other fields. Because of its closed-cell structure, it is difficult to recycle and remelt during the recycling process.

Challenges:

XPS has a higher strength-to-density ratio, so it requires stronger mechanical force to crush and compress. Additionally, XPS can produce harmful gases during recycling, so it is important to handle the environmental and safety issues during the recycling process.

Appropriate Equipment:

- Heavy-duty Crusher: Specifically designed to handle high-density materials and crush them.

- Hot Melting Machine: Melt and extrude XPS foams into dense long strips for the next step of the recycling process.

- Dust Removal Equipment: To ensure the safety and environmental protection of the recycling process, dust removal equipment is needed for gas treatment.

Conclusion

There are different challenges in recycling different types of foam. Understanding the commonalities and differences in their recycling will help improve recycling efficiency. The above are the differences. To learn more about the commonalities and other recycling knowledge, please visit our website about foam plastic recycling or click the link at the bottom right for professional team assistance online.