As the global emphasis on environmentally friendly packaging increases, biodegradable paper egg trays have become a mainstream green packaging option, widely used by egg farms, food processors, and packaging suppliers.

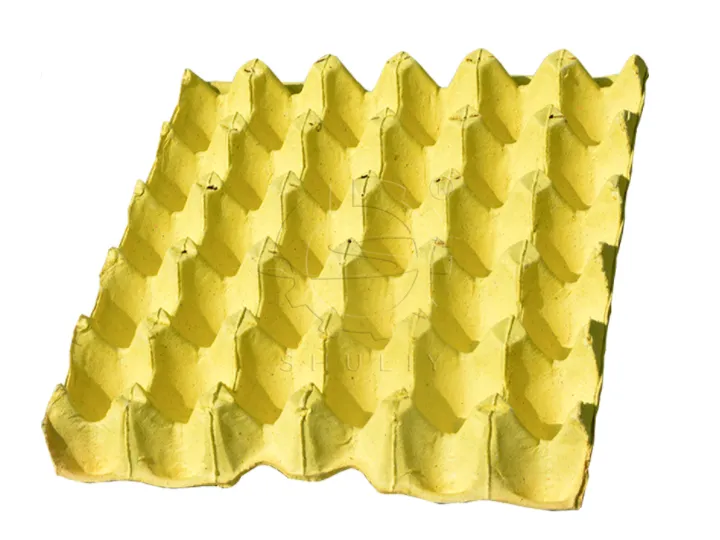

Shuliy offers a wide range of egg crate making machines that help customers efficiently produce low-cost, environmentally friendly paper trays with good protective properties, promoting resource recycling and sustainable development. The thickness, color, shape, and size of the egg trays can be customized during the production process to meet the needs of different markets and customers.

What is the egg tray making machine?

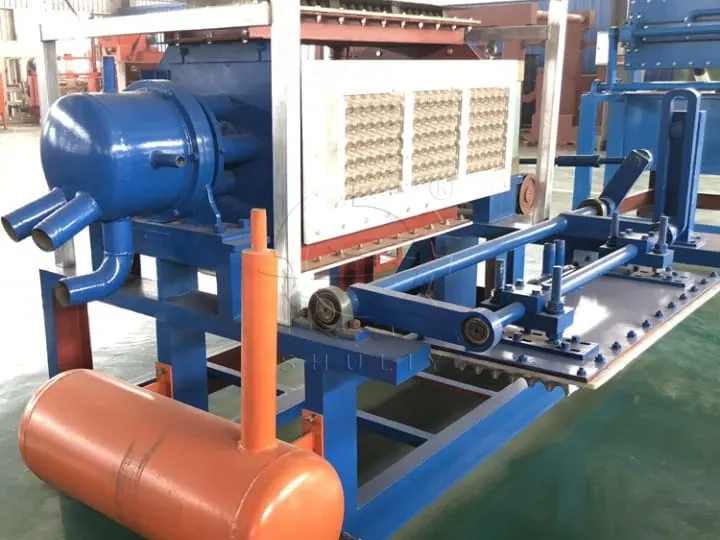

An egg crate making machine, also known as an egg tray molding machine or an egg carton making machine, is used to produce molded pulp trays from recycled paper. These trays offer a safe and biodegradable solution for storing, transporting, and selling eggs.

The process involves three key stages:

- Pulping – Waste paper (newspapers, cartons, office paper, etc.) is broken down into pulp using a pulper.

- Molding – The pulp is vacuum-formed into egg trays using precision molds.

- Drying & Finishing – Wet trays are dried using natural sun drying or automated ovens, then stacked and packed.

Egg crate making machine model list

We offer a wide range of egg tray molding machines designed to suit various production scales.

One-side egg crate making machine

| Model | WJ-1000-3*1 | WJ-1500-4*1 |

| Mold Faces | 3*1 (1 side, 3 faces per side) | 4*1 ( 1 side, 4 molds per side) |

| Capacity | 1000 pcs/h | 1500 pcs/h |

| Power | 38 KW | 38 KW |

| Machine Weight | 2500 kg | 3000 kg |

| Machine Size | 2600*2200*1900 | 2800*2200*1900 |

| Paper Consumption | 80 kg/h | 120 kg/h |

| Water Consumption | 160 kg/h | 240 kg/h |

four-side egg tray making machine

| Model | WJ-2500-3*4 | WJ-3000-4*4 |

| Mold Faces | 3*4 ( 3 molds per side, 4 sides) | 4*4 (4 sides, 4 molds per side) |

| Capacity | 2500 kg/h | 3000 kg/h |

| Power | 55 KW | 60 KW |

| Machine Weight | 4000 kg/h | 4800 kg/h |

| Machine Size | 2900*1800*1800 | 3250*1800*1800 |

| Paper Consumption | 200 kg/h | 240 kg/h |

| Water Consumption | 400 kg/h | 480 kg/h |

eight-side egg tray manufactuing machine

| Model | WJ-4000 – 4*8 | WJ-5000-5*8 | WJ-7000-6*8 |

| Mold Faces | 4*8 ( 8 sides, 4 molds per side) | 5*8 (8 sides, 5 molds per side) | 6*8 ( 8 sides, 6 molds per side) |

| Capacity | 4000-5000 kg/h | 5000-6000 kg/h | 6000-7000 kg/h |

| Power | 95 KW | 95 KW | 120 KW |

| Machine Weight | 7000 kg | 8000 kg | 10000 kg |

| Machine Size | 3250*2300*2500 | 3700*2300*2500 | 3200*2300*2500 |

| Paper Consumption | 320 kg/h | 400 kg/h | 480 kg/h |

| Water Consumption | 640 kg/h | 800 kg/h | 960 kg/h |

Customizable Mold Design & Versatility

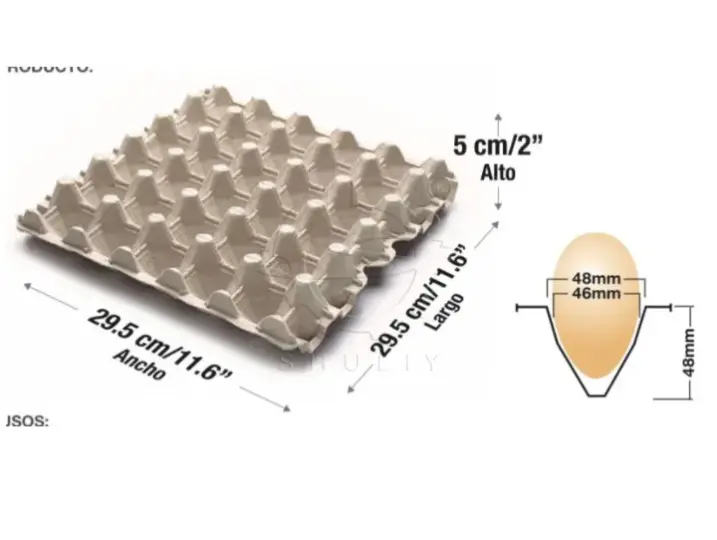

Our egg crate making machines are equipped with stainless steel molds that can be tailored in:

- Tray shape (egg trays, egg cartons, fruit trays, bottle trays, etc.)

- Cavity size and count (30-hole standard, 12-hole, 6-hole, etc.)

- Material (anti-corrosion and easy-maintenance stainless steel)

This allows customers to use a single egg tray manufacturing machine for various molded pulp products beyond egg packaging.

Eco-Friendly & Cost-Efficient Solution

Egg crates produced by our machines are:

- Fully biodegradable

- Made from recycled paper

- Lightweight yet durable

- Color-customizable with pigment injection

From a cost perspective, production can be as low as $0.01–0.03 per tray, depending on drying method, labor, and fuel used. Our system supports low energy consumption and optimized pulp-to-tray efficiency.

Intelligent Factory Layout & Automation Ready

Each system is designed with flexible workshop layouts in mind:

- Compact footprint for small setups

- Modular expansion options

- Integrated conveyors, stacking machines, and packaging systems

Whether you choose a manual, semi-automatic, or fully automatic egg tray making line, we ensure stable output, low maintenance, and scalable performance.

get egg crate making machine price!

If you’re looking for a reliable, cost-effective, and sustainable solution, our egg crate making machine is your best choice. We’ll help you select the right model, design the full egg tray production line, and start producing high-quality trays in no time!