Das Entfernen von Stahldraht aus Altreifen ist der erste und kritischste Schritt im Reifenrecyclingprozess. Eine zuverlässige Reifenabziehermaschine gewährleistet eine sichere und effiziente Vorverarbeitung, indem sie den harten Draht aus der Seitenwand des Reifens entfernt. Dies schützt nachgeschaltete Zerkleinerer und Brecher, verbessert die Verarbeitungsgeschwindigkeit und ermöglicht es, den recycelten Stahl als wertvolles Schrottmaterial zu verkaufen.

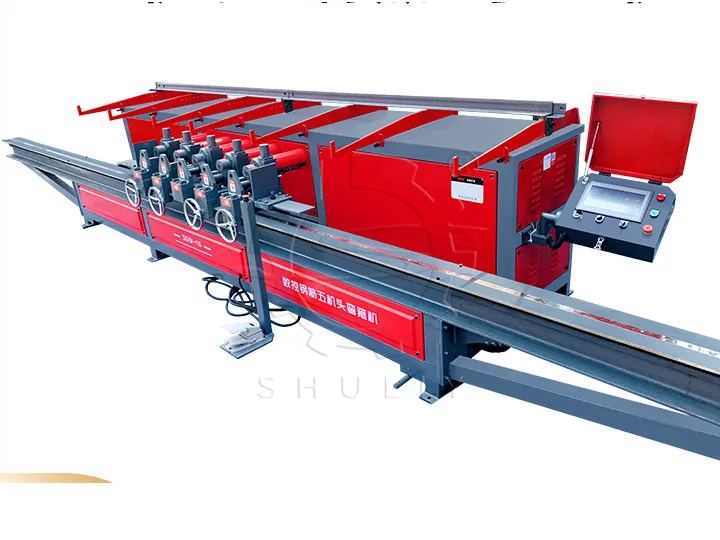

Shuliy Machinery bietet eine vollständige Palette von Reifenabziehern für sowohl Standardreifen als auch schwere OTR-Reifen an, die verschiedene Recyclingkapazitäten und Automatisierungsgrade unterstützen.

Was ist die Reifenabziehmachine?

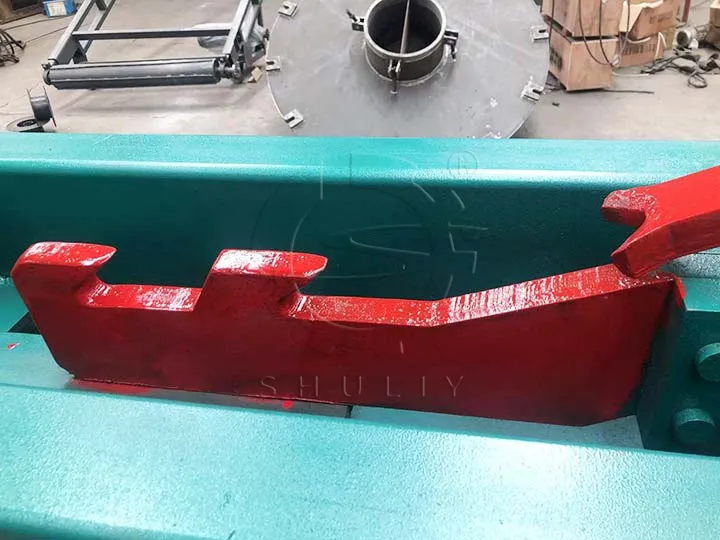

Ein Reifenentlader, auch bekannt als Drahtziehmaschine für Reifen, nutzt hydraulische Energie, um den Stahlring aus dem Wulstbereich eines Altreifens herauszuziehen. Dieser Draht, wenn er nicht entfernt wird, kann die Zerkleinerungsmesser erheblich beschädigen und die Effizienz der Geräte beeinträchtigen.

Der Prozess des Reifenentbeadens ist einfach, aber effektiv:

- Der Reifen wird auf die Maschinenplattform geladen.

- Ein hydraulischer Haken wird in den Wulstbereich eingeführt.

- Der Haken zieht den Stahlring heraus.

- Der saubere Reifen wird für weiteres Schneiden oder Zerkleinern entfernt.

Drei Arten von Maschinen zum Ziehen von Reifenstahldrähten.

Shuliy bietet drei Haupttypen von Maschinen zur Drahtentfernung aus Reifen an, die jeweils für unterschiedliche Reifengrößen und Verarbeitungsbedürfnisse ausgelegt sind:

Einzelhaken-Reifenentstahler (für 900–1200 mm Reifen)

- Entfernt Stahl von einer Seite pro Zyklus

- Ideal für Kleinbetriebe

- Kapazität: 20-30 Reifen / h

- Leistung: 11 KW

Doppelhaken-Reifenentstahler (für 900–1200 mm Reifen)

- Entfernt Draht von beiden Seiten gleichzeitig

- Erhöht die Effizienz und reduziert den Arbeitsaufwand

- Kapazität: 40-50 Reifen / h

- Leistung: 18,5 KW

OTR-Reifen-Drahtziehmaschine (für 1800–4000 mm Reifen)

- Robuste Struktur für große Ingenieurreifen

- Verstärkter Haken und Rahmen für dicke Stahlringe

- Kapazität: 1 Reifen alle 2 Minuten

- Leistung: 22+3 KW

- Geeignet für das Recycling von Reifen in Bergbau, Bauwesen und Industrie

Endprodukte und Anwendungen der Maschinen zur Drahtentfernung aus Reifen

Der Reifenentmantler produziert zwei Hauptprodukte:

- Stahldrahtring

Hochfeste, kontaminationsarme Stahlringe, die an Schrotthändler oder Stahlwerke zum Einschmelzen verkauft oder als Brennstoff in Zementöfen verwendet werden können. - Gummireifen-Körper

Sobald der Stahl entfernt ist, kann der Reifen weiterverarbeitet werden mit einer Reifenschneider, Reifenzerkleinerer, oder Gummigranulator. Für OTR-Reifen wird der OTR-Debeadder häufig mit einer OTR-Reifen-Schneidemaschine kombiniert, um eine vollständige Vorbehandlung zu gewährleisten.

Warum Shuliy Reifenentmantelmaschinen wählen?

- Bewährte Designs, die in Reifenrecyclinganlagen weltweit verwendet werden

- Starke hydraulische Systeme für einen stabilen und präzisen Betrieb

- Kompatibel mit halbautomatischen und vollautomatischen Recyclinglinien

- Anpassungsoptionen für verschiedene Reifengrößen oder -layouts

- Umfassende Unterstützung nach dem Verkauf und technische Unterstützung verfügbar

Fordern Sie noch heute ein Angebot an

Suchen Sie einen Reifenentmantler zum Verkauf, der zu Ihrem Produktionsmaßstab und Ihren Reifentypen passt? Kontaktieren Sie noch heute Shuliy Machinery für fachkundige Beratung und ein wettbewerbsfähiges Angebot. Egal, ob Sie 900 mm Lkw-Reifen oder 4000 mm OTR-Reifen verarbeiten, wir haben die richtige Lösung für Ihre Recyclinglinie.