Turning waste tires into valuable resources is no longer a challenge. With our advanced rubber granulator integrated with high-performance magnetic separators, recycling companies can efficiently convert old tires into fine rubber powder. This complete system is widely recognized in the tire recycling industry for its durability, high output, and ability to produce clean, steel-free powder.

Why do we Need a rubber granualtor?

A rubber granulator (also known as a tire grinding machine or rubber tire grinder) is the core equipment in a tire recycling line. It transforms shredded tire blocks into mesh tyre powder of various sizes, ready for reuse in multiple industries such as rubber flooring, playground surfaces, sports fields, and reclaimed rubber production.

For businesses looking for a tire grinder for sale, investing in a modern rubber powder machine ensures not only high output but also stable quality and significant cost savings in raw materials.

Raw Materials and Final Products of our tire grinder for sale

- Raw Materials: Whole waste car tires, truck tires, and OTR tires pre-cut into 30–100mm blocks.

- Final Products:

- Mesh tyre powder: Fine rubber powder from 5–40 mesh, used for producing rubber mats, asphalt modifiers, shoes, and industrial rubber products.

- Steel wire: Removed by the magnetic separator and sold for smelting or recycling.

- The end result is a clean, high-quality rubber powder that can be sold at a higher market value.

Main Advantages of the Rubber Powder making machine

- Versatile Grinding Capability: Capable of producing different mesh sizes from coarse particles to ultra-fine powder.

- Magnetic Separation System: Ensures that steel wires are completely removed, guaranteeing clean powder.

- High Output, Flexible Models: From 250 kg/h to more than 2300 kg/h, suitable for both small workshops and large recycling plants.

- Durability and Safety: Made of wear-resistant materials, ensuring long service life and stable operation.

- Eco-Friendly Recycling: Supports the circular economy by reducing waste and producing valuable recycled products.

Whether you are searching for a tire grinder for sale or upgrading your recycling line, our rubber tire grinder is a cost-effective solution.

Technical Parameters of our Rubber Granulator System

| نموذج | Mesh Size | Capacity (kg/h) |

|---|---|---|

| SL-350 Line | 10–40 mesh | 80–300 |

| SL-400 Line | 10–40 mesh | 150–500 |

| SL-450 Line | 10–40 mesh | 200–600 |

| SL-560 Line | 10–40 mesh | 300–1000 |

| SL-560D Line | 10–40 mesh | 800–1600 |

| SL-660 Line | 10–40 mesh | 900–2300 |

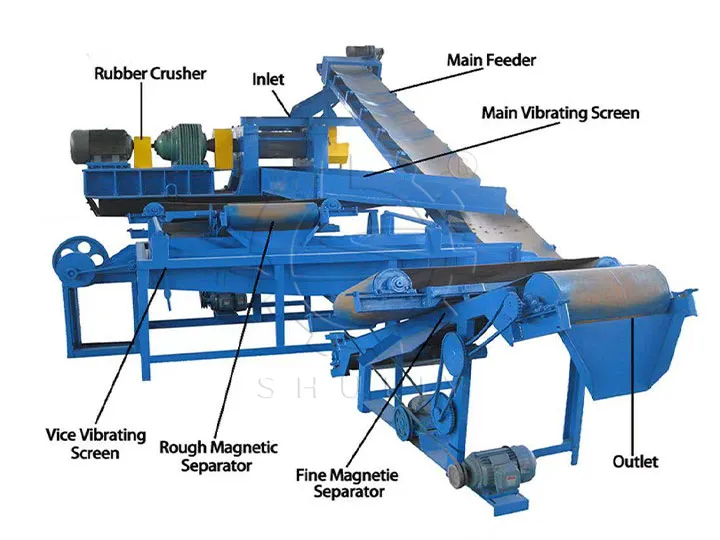

Working Principle of the Tire Grinding Machine

- Pre-Cutting: Large waste tires are cut into blocks by the hydraulic tire cutter.

- Granulation Process: The tire blocks are fed into the rubber granulator, where rotating blades grind them into smaller granules.

- Fine Grinding: The rubber tire grinder continues reducing the size to produce mesh tyre powder of 5–40 mesh.

- Magnetic Separation: Steel wires are separated by a strong magnetic separator.

- Fiber Removal: Nylon fibers are filtered out to ensure pure rubber powder.

- Final Output: Clean, fine rubber powder ready for reuse in multiple industries.

This streamlined process ensures maximum recycling efficiency and minimal waste.

Application Fields of Mesh Tyre Powder

- Sports and Leisure: Running tracks, playground surfaces, and sports turf.

- Construction Industry: Asphalt modification for road paving, waterproof membranes.

- Industrial Use: Rubber mats, conveyor belts, shoe soles, and automotive rubber parts.

- Reclaimed Rubber: Used as raw material for new rubber products.

By investing in a tire grinding machine, recyclers can expand their business into different industries with profitable outputs.

Related Tire Recycling Equipment

To build a complete recycling line, the rubber granulator works together with other machines:

- Tire Wire Drawing Machine: removes steel bead wires before shredding.

- Hydraulic Tire Cutter: cuts large OTR tires into smaller sections.

- Tire Mulch Machine: for producing fine mesh tyre powder.

Get Your Customized Tire Grinding Line!

If you are looking for a tire grinder for sale or want to upgrade your recycling line with a reliable rubber powder machine, our rubber granulator with magnetic separators is your best choice. It guarantees high efficiency, clean output, and long-term durability.

👉 Contact us today to get a customized solution for your tire recycling project and start producing high-value mesh tyre powder profitably.