إطارات النفايات صعبة التحلل. بالنسبة لمعيدي التدوير، فإن الخطوة الأولى والأكثر أهمية هي إزالة الجوانب الجانبية. لماذا؟ لأن فصل الجوانب الجانبية يجعل بقية الإطار أسهل في التعامل والقطع والمعالجة. هنا يأتي دور آلة قطع جوانب الإطار (المعروفة أيضًا بآلة قطع حلقات الإطار أو آلة قطع جوانب الإطار).

لماذا نحتاج إلى قاطع جوانب الإطار؟

إزالة الجدار الجانبي أمر ضروري في إعادة تدوير الإطارات الحديثة لثلاثة أسباب رئيسية:

- يحرر كرات الصلب

يحتوي الجدار الجانبي على حلقة سلكية فولاذية سميكة، يجب فصلها قبل المزيد من التقطيع. يجعل القاطع المخصص هذا الأمر سهلاً وآمنًا. - يحسن كفاءة العمليات اللاحقة

بعد إزالة الجدار الجانبي، يصبح جسم الإطار المتبقي (القمة) أسهل في التقطيع إلى شرائح وكتل باستخدام آلة قطع شرائح الإطارات أو قاطع كتل الإطارات. - يحمي الآلات

يؤدي قطع الحلقة أولاً إلى تقليل التآكل على أجهزة التقطيع والطحن والتكسير - مما يوفر الوقت والشفرات وتكاليف الصيانة.

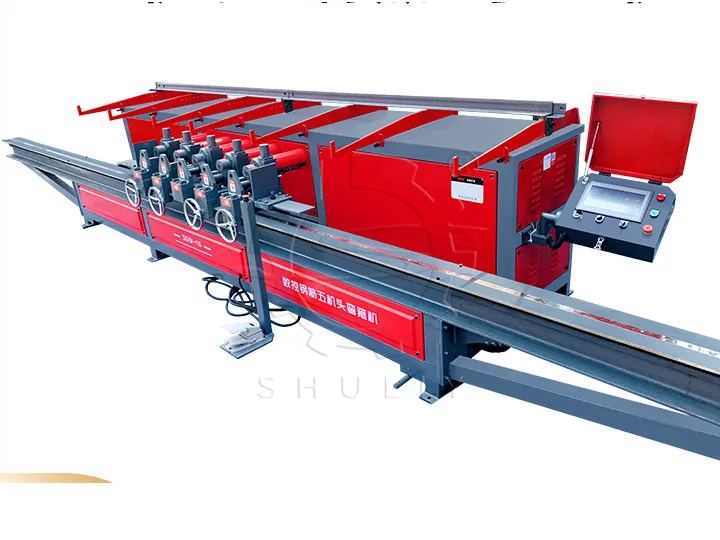

المواصفات الرئيسية لآلة قطع الجدار الجانبي للإطارات شولي المعروضة للبيع

تم تصميم قاطع جدار الإطار لدينا لتقديم Cuts نظيفة ودقيقة مع جهد minimal. إنها الآلة المثالية كنقطة دخول لأي خط إعادة تدوير إطارات شبه أوتوماتيكي أو إعداد معالجة إطارات مستقل.

- قوة المحرك4+0.75 كيلو واط

- سعةحوالي 40 إطار في الساعة

- أقصى حجم للإطاريدعم إطارات السيارات والشاحنات، إلخ (أقل من 1200 مم)

- قطر القطعتركيب حلقة قابلة للتعديل لأحجام مختلفة

- مادة الشفرة: فولاذ سبائكي مقسى، قابل لإعادة الطحن

- الهيكل: مساحة صغيرة، غطاء أمان متضمن

ما الذي يجعل آلة قطع الجدار الجانبي للإطارات لدينا مميزة؟

- تركيب قابل للتخصيصقابل للتكيف مع أحجام الإطارات المختلفة

- تشغيل سهلبسيط وآمن وسريع

- مصمم للاستخدام المكثفيتعامل مع إطارات راديالية ذات حزام فولاذي بسهولة

- استهلاك منخفض للطاقةمحرك فعال بعزم دوران عالٍ

- آمن ومستقرمنطقة قطع مغلقة مع تصميم قاعدة مضادة للانزلاق

كيف يعمل قاطع حلقات الإطارات؟

تتمثل عملية العمل لآلة قطع الجدار الجانبي للإطارات فيما يلي:

- ضع الإطار أفقيًا على المنصة الدوارة

- قم بضبط موضع الحلقة باستخدام ذراع التثبيت

- قم بتشغيل شفرة القطع - دورة واحدة سلسة تقطع من خلال الجدار الجانبي

- قم بإزالة الجدار الجانبي بشكل نظيف واستعد للخطوة التالية

تطبيقات آلة قطع جدار الإطار

يمكن استخدام قاطع جوانب الإطارات لدينا على نطاق واسع من قبل:

- مصانع إعادة تدوير الإطارات

- مصنعي مسحوق المطاط والكرات الصغيرة

- معالجي النفايات البلدية

- ورش استعادة الإطارات الصغيرة والمتوسطة

البدء بقطع جدار جانبي نظيف هو المفتاح لمعالجة موثوقة في المراحل التالية.

تكامل خط إعادة التدوير الكامل

قم بمطابقة هذه الآلة مع:

- 🔗 آلة قطع شرائح الإطارات – قطع جسم الإطار المتبقي إلى شرائح

- 🔗 قاطع كتل الإطارات – تقليلها أكثر إلى كتل موحدة

- 🔗 خط إعادة تدوير الإطارات شبه الأوتوماتيكي – سير عمل إعادة تدوير قابل للتعديل وقابل للتوسع

ابدأ عملك في إعادة تدوير الإطارات!

هل تبحث عن طريقة فعالة من حيث التكلفة لبدء عملية إعادة تدوير الإطارات الخاصة بك؟ توفر لك آلة قطع جوانب الإطارات لدينا المتانة والكفاءة والنتائج النظيفة من أول قطع. اتصل بنا الآن للحصول على عرض مخصص ودعم فني!