As a kind of common plastic material used in construction, plumbing, etc., PVC has great value. However, it is not biodegradable and doesn’t break down on itself, which results in severe pollution.

To maximize the value of PVC and facilitate circular economic development, this article offers a comprehensive guide to how to recycle PVC pipe.

The common problems during PVC Pipe Recycling

PVC contains chlorine, plasticizers, anti-aging agents, etc., which may release toxic gases during the heating process in recycling. Therefore, it’s important to ventilate and select a machine that is safe and easy to operate during the recycling process.

Shuliy’s advanced PVC pipe recycling solution

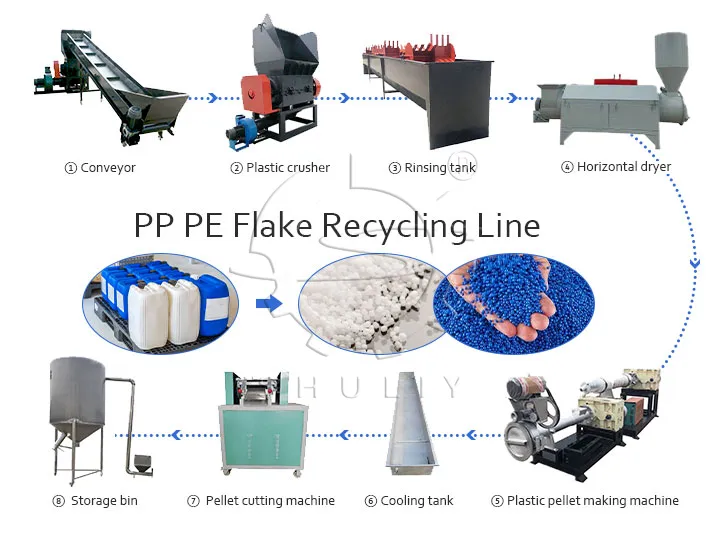

How to recycle PVC pipe? Shuliy employs the physical recycling method to reprocess waste PVC pipes into recycled PVC plastic pellets, which can be utilized in the manufacturing of new plastic products. The steps involved are as follows:

collecting&Sorting

- Collecting: PVC pipes are commonly collected in construction sites, households, etc.

- Sorting: PVC pipes commonly contain metal, rubber fittings, and other impurities, which should be carefully removed.

crushing

The Shuliy plastic crushing machine can cut 100~3000kg of plastics per hour, transforming large PVC pipes into small pieces. The smaller fragments are more convenient to transport and process.

washing

Through washing by washing tanks, remove a large quantity of dirt, debris, and other impurities to ensure the purity and cleanness of the final products.

pelletizing

- The plastic pelletizer machine consists of a plastic extruder, a cooling tank, a plastic pellet-making machine, and so on.

- In this pelletizing process, the plastic is melted and remolded into long strips. After cooling, the plastic pellet-cutting machine cuts plastic strips into uniform granules as required.

In addition, the Shuliy granulator can precisely control the production temperature through the intelligent control panel, preventing toxic gases from being generated by high temperatures. Equipped with filtration systems, the gases can also be captured by our machines.

drying&storage

The final step involves dewatering the plastic pellets with a horizontal dryer and then storing them in a storage bin for reproduction. These pellets can be used to manufacture various products, including pipes and other applications.

6 advantages of the shuliy PVC Recycling Line

Shuliy machines have been successfully exported to many countries with rich experience and several advantages.

- Customizable for special production needs.

- A one-year warranty and on-site installation

- Safe and simple to operate.

- High-quality with CE&ISO certification.

- Provide free factory tour service.

- Provide detailed consultation service.

How to recycle PVC pipe effectively?

Shuliy provides professional plastic recycling machines for PVC, PP, PE, HDPE, etc. at a speed of 200kg~3t/h, which are suitable for all scales of factories. If you’re seeking premium PVC recycling machines, please feel free to contact us. I hope we can work together to boost your business!