Processing large volumes of heavy scrap demands equipment that is both powerful and exceptionally reliable. Inefficient machinery can lead to costly downtime and operational bottlenecks, directly impacting profitability.

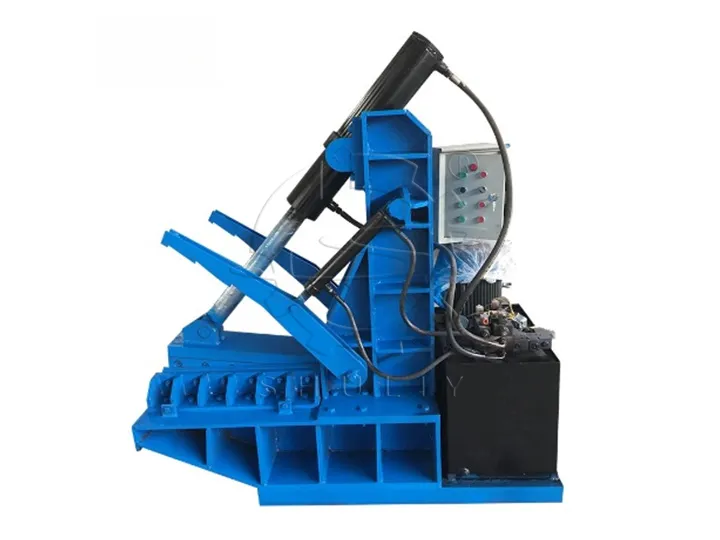

Our heavy-duty scrap shear is engineered to be the robust heart of your recycling operation. It combines immense cutting force with intelligent automation and a durable design, providing a definitive solution for processing everything from structural steel beams to dense industrial scrap.

Key Advantages of Our Heavy-Duty Scrap Shear

Our design philosophy focuses on three core pillars: power, efficiency, and durability.

- Immense Processing Power: With a formidable shear force (models available up to 1000 tons and beyond), this machine effortlessly cuts through materials that are impossible for smaller equipment. It cleanly processes thick plates, I-beams, pipes, and rebar.

- Automated Efficiency: The integrated PLC system automates the entire cutting cycle. This allows for continuous, high-throughput operation with a single operator, drastically reducing labor costs and improving consistency.

- Engineered for Durability: Built on a heavy-duty, stress-relieved steel frame and equipped with high-quality hydraulic components, our shear is designed for longevity in harsh environments. Replaceable wear liners in key areas ensure a long service life and simplified maintenance.

How It Works: The Working Principle of Gantry shear

The operation of our heavy-duty scrap shear is a streamlined, automated sequence designed for maximum efficiency:

- Loading: Scrap material is loaded into the large-capacity material box (silo) using a grapple, magnet, or front-end loader.

- Pre-Compression: A hydraulic lid or side-compression system compacts the loose material within the box, creating a denser charge.

- Feeding: A powerful hydraulic pusher cylinder advances the compressed material forward towards the shear mouth, feeding a specific length for cutting.

- Clamping & Shearing: A hydraulic hold-down clamp (pressing block) firmly secures the material. Then, the main shear head, driven by massive hydraulic cylinders, descends to perform a clean, powerful cut.

- Cycle Repeat: The shear head and clamp retract, and the pusher cylinder advances the next section of material. The cycle repeats automatically until the entire load is processed.

Technical Parameters of the hydraulic gantry shear

Below are the typical specifications for one of our popular models. We specialize in custom configurations to meet your specific needs.

| Parameter | Specification (Example: 850T Model) |

|---|---|

| Nominal Shear Force | 850 Tons |

| Material Box Size (L*W*H) | 8000*1900*900 mm |

| Max. Cutting Width | 2000 mm |

| Main Motor Power | 4*45 kW |

| Cycle Rate | 3-6 cuts/min |

| Control System | Siemens/Mitsubishi PLC with Touch-Screen HMI |

| Cooling Method | Air or Water Cooling System |

A Direct Impact on Your Operational Success

Investing in this gantry shear is a direct investment in your operational capability. The benefits are clear:

- Higher Material Value: Produce dense, furnace-ready scrap that commands premium pricing.

- Lower Operating Costs: Reduce your reliance on expensive manual labor and minimize energy consumption per ton.

- Increased Uptime: Our commitment to robust engineering and quality components means less downtime and more productive hours.

To receive a detailed quote or to discuss how a heavy-duty scrap shear can be configured for your specific materials, please contact our technical sales team! We also provide baling machines for your metal recycling business.