What is rPET Material?

RPET material aka recycled polyethylene terephthalate is a revolutionary eco-friendly fabric made from PET waste plastics and widely used as packaging material in various fields, including food, medicine, electronics, etc.

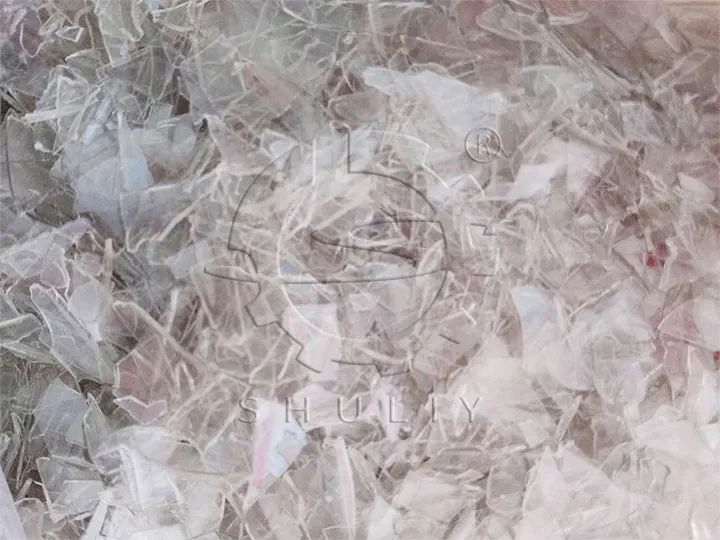

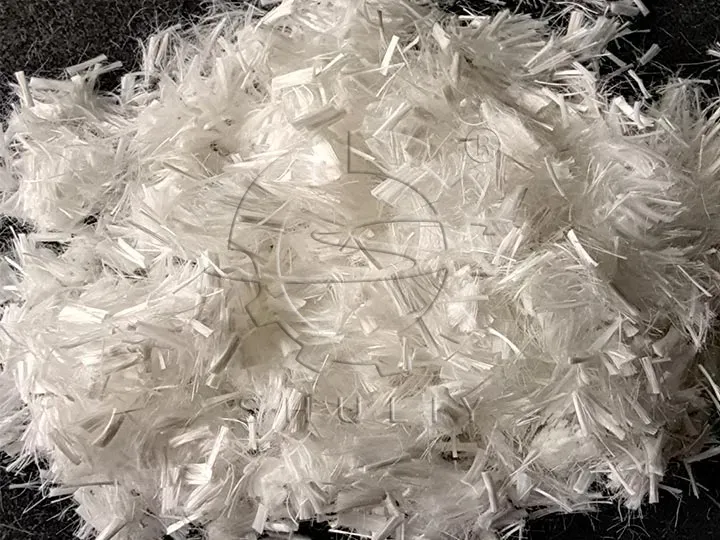

RPET plastics are manufactured by collecting, cutting, washing, and drying post-consumer and post-industry PET plastic bottles into uniform flakes, which greatly reduces production costs and boosts environmental protection.

Why and how do we use rPET materials?

Why do we use rPET Materials?

- RPET has similar physical properties to virgin PET and does not affect the quality of plastic products.

- Using rPET can reduce the production costs of new plastic products and reduce plastic waste.

- RPET can be modified in the recycling process to be used in a wide range of applications.

- As an essential role in circular economic development, recycling, and re-cycling can maximize the value of PET, reduce reliance on natural resources like petroleum, lowering the carbon footprint.

How do we use RPET plastic?

RPET materials can be used in many fields, including clothing, food packaging, detergent containers, the industrial sector, etc.:

- Clothing: rPET can be transformed into fibers, which is a crucial component of clothing, backpacks, and more.

- Food packaging: PET bottles can be recycled into rPET and then used in new PET bottle manufacturing.

- Detergent containers

If you are manufacturers or recyclers of the above fields, you can consider producing rPET to make profits. Shuliy can provide solutions about how to recycle PET plastic bottles: PET Recycling Machine For Plastic Water Bottle 500kg/h~6T/h

Tips for the rPET manufacturing process

PET recycling process

- Total Steps: The rPET manufacturing process involves collecting, sorting, label removal, washing, and drying.

- Collecting and sorting: Separately recycle PET bottles and other materials to ensure the rPET flakes purity.

- Label removal: The label removal rate is up to 98% and the resident labels need to be removed manually.

- Washing: There are 3 washing steps: friction washing, separation washing, and hot washing, We can add some detergent during the washing process to further remove impurities.

- Drying: If your raw materials quantity is large, you can add a dryer tube and a wind separator.

Common problems

- PET bottles can be recycled and recycled to maximize their value. However, the viscosity of the bottle will decrease, so it needs to be used with virgin PET.

- RPET used for food packaging needs to pass safety inspections.

Conclusion

RPET has premium physical properties and wide applications, promoting the construction of green ecological civilization and reducing costs. Read this article, do you still have questions about what is rPET material, why and how do we use it? If you’re confused or interested, please feel free to contact us.