what is the heating system in a plastic extruder?

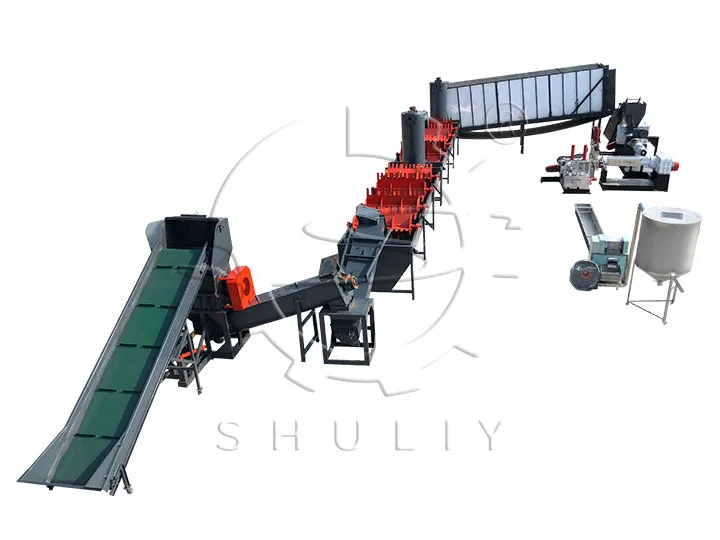

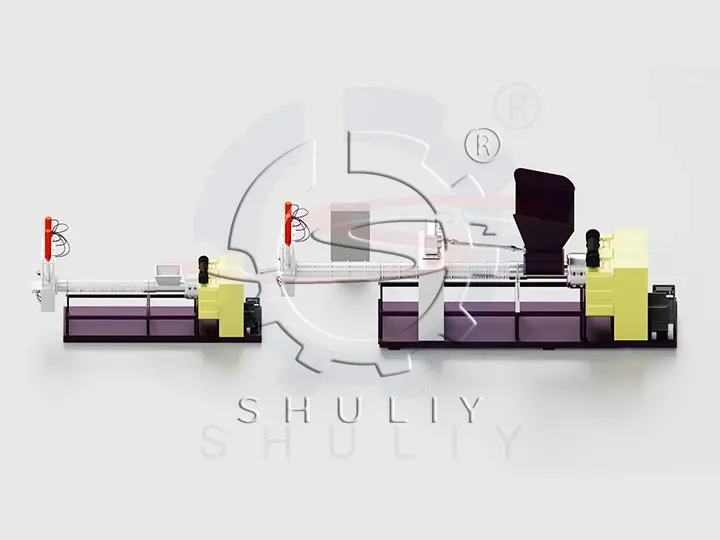

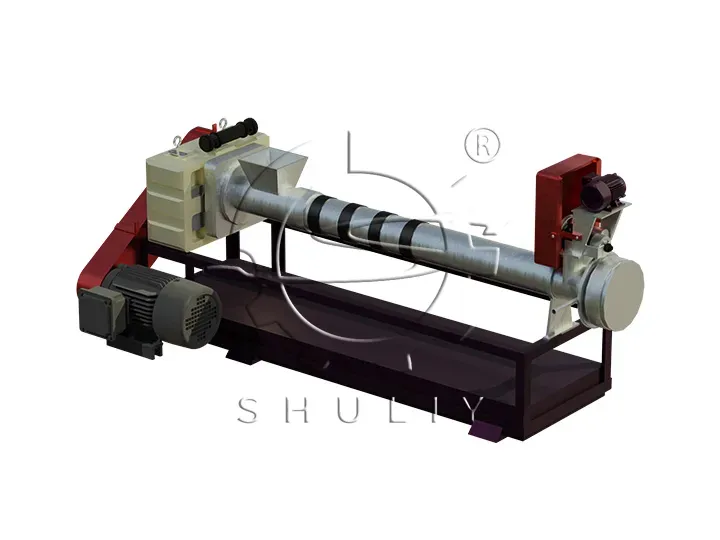

During the plastic pelletizing process, the washed plastics undergo a series of steps including melting, extrusion, cooling, and cutting to transform them into uniform pellets as required sizes ultimately.

Consequently, the heating system assumes a pivotal role in facilitating plastic granulation by effectively melting the plastic into a molten state. There are 3 kinds of heating systems equipped with Shuliy plastic extruders.

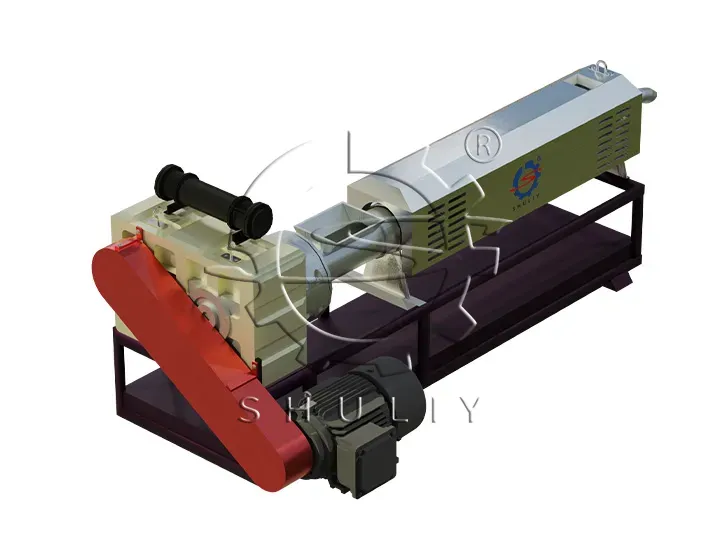

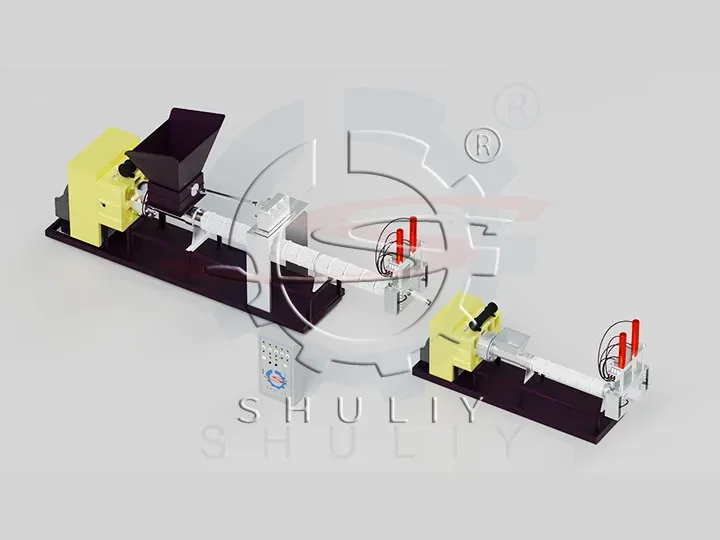

electromagnetic heating system application

Electromagnetic heating generates heat within the metal barrel of the granulator through an electromagnetic reaction, causing the temperature to rise quickly and melt the plastic.

Advantage:

- It can heat plastics rapidly, reducing energy costs. Compared with other heating methods, the electromagnetic heating system can reduce electricity consumption by up to 30-70%.

- It’s simple for staff to precisely control the temperature by control panel.

Application:

- It is suitable for large-scale granulation scenarios where high efficiency and precise temperature control are required.

- Pay attention to the proper functioning of the electromagnetic coil and avoid any impurities such as dust that may affect the machine’s performance.

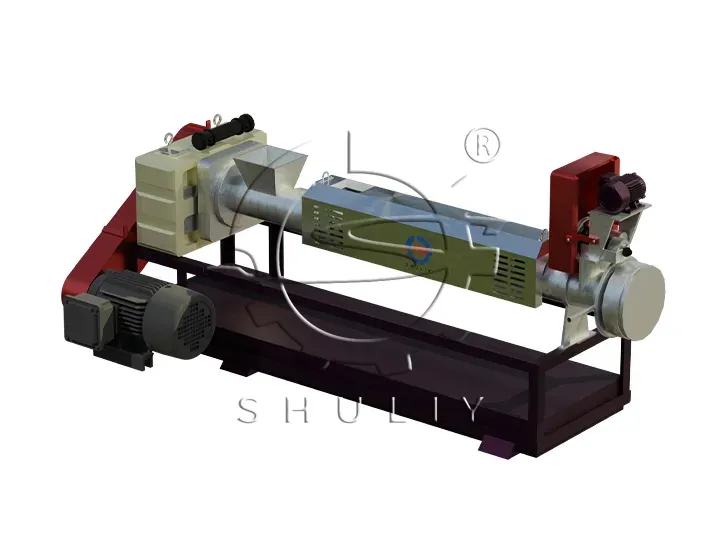

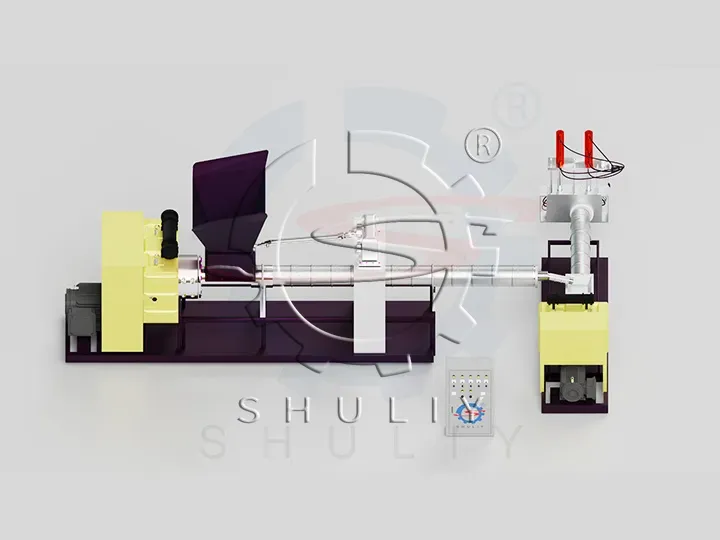

what does a ceramic heater do?

Ceramic heaters generate heat through resistance and evenly distribute the heat to the plastics in the barrel to melt them.

Advantage:

- With less electricity usage, the energy costs of a ceramic heater can be reduced.

- Provide even heat distribution with good stability.

Usage:

- Ceramic heating is suitable for medium-sized production operations that require even temperature control.

- Regular cleaning of the ceramic surface is necessary to ensure optimal heating performance while taking care not to damage the ceramic.

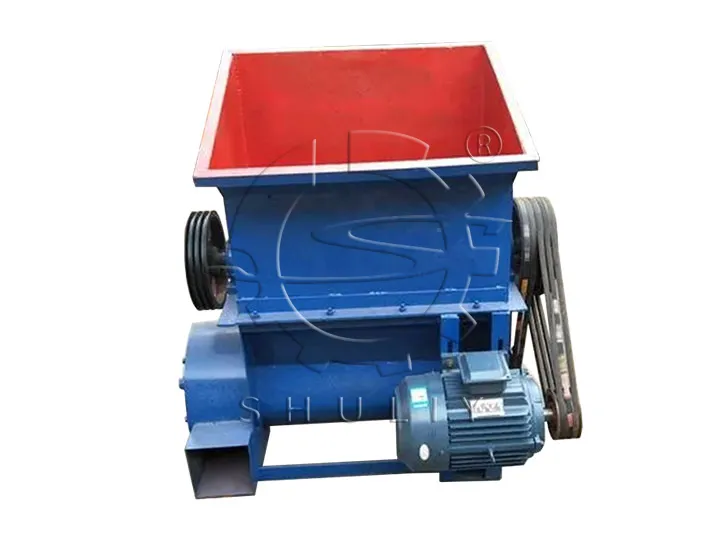

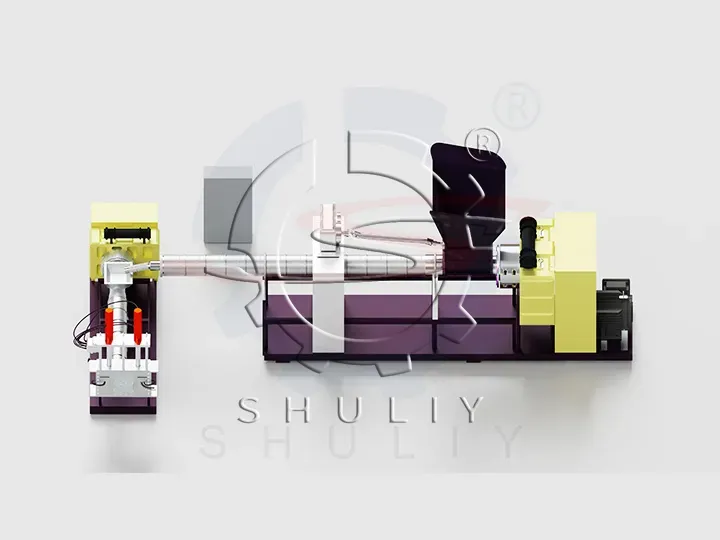

iron heating system for plastic pelletizing

The iron heating system utilizes iron or iron wire transferring heat to plastics in the barrel of the plastic pelletizer machine.

Advantage:

- Iron plate heating is the most traditional heating method, with a low initial cost.

- The system is simple and easy to maintain.

application:

- It’s suitable for small-scale granulation operations with a low budget and low production requirements.

- Check the iron plate regularly to see if it is worn out to avoid excessive energy loss.

Conclusion

Each heating method has its advantages and disadvantages. The specific choice depends on the production needs. The iron heater features a low initial cost, the ceramic heating system can provide an even distribution of heat, and the electromagnetic heating system has the characteristic of precisely controlling the temperature.

If you have any questions, you can contact the staff for consultation. As a professional plastic recycling machine supplier, Shuliy provides entire plastic recycling lines. Looking forward to your news!